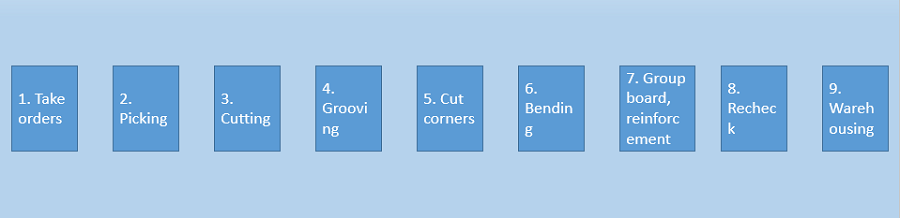

Processing essentials of each process:

(1) Aluminum sheet orders:

① After the operator receives the processing order, he must understand its intention and check whether the data indicated in the figure is consistent with the related data of the order

combine.

② Under the conditions that match, proceed with material planning and go through the procedures for picking up materials.

(2) Aluminum sheet picking:

①According to the type, specification and color of the materials to be used according to the order, after the warehouse clerk approves and signs, the materials are verified according to the order quantity.

②For transportation out of the warehouse, most of them are cranes; less is manual, and they are to be cut before being transported to the cutting machine.

(3) Aluminum sheet cutting:

①When cutting the composite board with an imported cutting machine, first adjust the positioner to the required size, cut a small point first, and check the size is

If it does not meet the required size, start cutting when it matches, and adjust it until it matches.

②When the composite board is cut, the cutting direction must be from left to right, from top to bottom, no reverse cutting is allowed, and the surface of the plate must be upward.

When two people are cutting together, they must use a simple hand or a password to indicate that they can cut, and one operator can depress the clutch.

③ After cutting, check whether the data of the cut plate is consistent with the processing sheet, and the error is allowed to be ±1.0mm.

④Put the plate lightly on the cleaning platform to avoid damage to the surface of the plate.

(4) aluminum sheet groove:

① First, check whether the materials used in the cutting plate data meet the requirements of the processing order.

②When grooving, the processing order drawing must be re-analyzed, confirmed and shaped.

③The operation of this item must require one person to be responsible for the control. The direction of the planing should be from left to right, from top to bottom, and no reverse cutting is allowed.

It must be sufficient and stable, and the positioning wheel must be closely attached to the composite board, otherwise the groove depth will be inconsistent.

④ Adjust the monitor to the required size when planing.

If it must be according to the planing requirements of the composite board, the depth of the planing must ensure that the polyethylene thickness of the decorative back is between 0.3mm and 0.5mm.

The width of the planer slot is between 3mm and 4mm, which shall not affect the appearance of the back surface finish. The size error of the slot position is allowed to be ±0.5mm.

⑤ After planing, put it lightly to avoid damage to the finish.

(5) Chamfering of aluminum sheet:

It must be punched on the punching machine according to the position shown in the figure, and the cutting angle is not allowed to exceed the center line of the planer.

(6) Bending of aluminum sheet:

①Be careful not to bend repeatedly to avoid fatigue damage. Bend at most twice, and the allowable size error is ±1.0mm.

②After bending, use the back of the wallpaper knife to lightly scratch the protective film of the composite board. Be careful not to scratch the board surface, and the position is 4mm away from the bending point.

left and right, and then remove the protective film.

(7) Aluminum sheet group board and reinforcement:

①Use isopropyl alcohol/water mixture (1:1) or xylene to clean the joints between the composite board, the frame, the reinforcing ribs and the 3M tape.

②The 3M tape is first bonded with the frame and reinforcing ribs. During operation, do not touch the 3M after tearing the film with hands or other objects.

Tape and cleaned surfaces.

③Sit the attached frame with 3M tape into the composite board box, tap the attached frame with your hand or a rubber hammer to make the composite board bend into the box.

In the hook groove of the attached frame, the 3M tape and the composite board are firmly bonded, and the gap between the folding seam of the composite board is less than 0.4mm.

④ According to the requirements of the design drawing, use the drilling template to drill holes, the distance between the blind rivets is 350mm, and the hole arrangement is from both ends to the middle.

Then, install self-tapping screws or blind rivets.

⑤ The reinforcing rib is closely attached to the composite board, and the two ends of the reinforcing rib and the folded edge of the composite board are connected by self-tapping screws or blind rivets.

Nail, taking care not to damage the panel finish.

(8) Aluminum sheet re-inspection:

①The allowable deviation of the length and width of the assembled plate is ±1.5mm; the allowable deviation of the diagonal dimension is less than or equal to 2.5mm; the plate thickness is ±1.5mm.

0.5mm; the allowable deviation of the angle of the corner plate is ±0.5°, exceeding this data is an unqualified product.

② Review whether each processing procedure is carried out as required and whether the processing effect is qualified.

(9) Storage of aluminum sheet:

After passing the inspection, the veneer and the veneer are placed face to face, and placed on the designated finished shelf at an angle of 80° to the horizontal. When transporting, pay attention to

The plate cannot be lifted horizontally, and it is required to be lifted from the side to avoid deformation of the plate.