The aluminum honeycomb core has a sharp, transparent hole wall without burrs. Suitable for high-quality core composite boards. It can disperse the pressure in the direction of the panel, make the panel receive uniform stress, and ensure that the panel can maintain high temperature even in a large area. Flatness. This article summarizes the dry hanging process of the finished aluminum honeycomb decorative panel in the bathroom, shows the effect of the installation, and then understands the comparison and analysis of the dry hanging structure of the finished aluminum honeycomb decorative panel and the traditional wet work.

Aluminum honeycomb panel dry hanging process

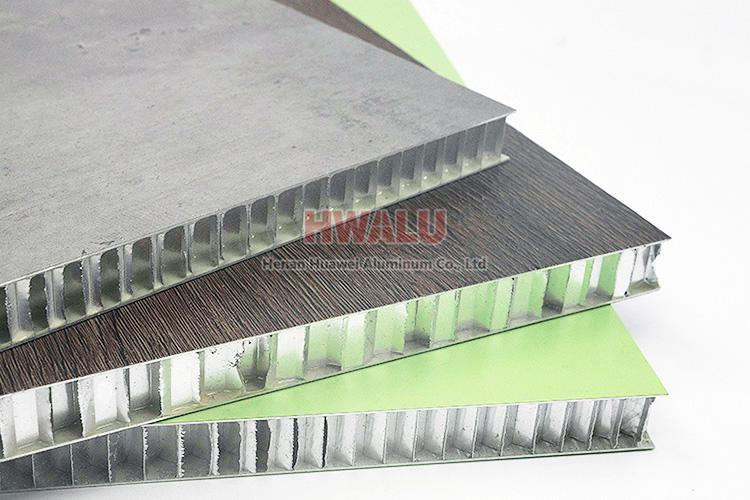

Honeycomb aluminum sheet

The honeycomb aluminum panel is a series of metal composite panels developed by combining aviation composite honeycomb panel technology. The utility model adopts a "honeycomb sandwich" structure, that is, a high-strength alloy aluminum plate coated with a weather-resistant decorative coating as a composite plate, which is made of high-temperature and high-pressure composite materials on the surface, the substrate and the surface. Aluminum honeycomb core. The bathroom area adopts finished aluminum honeycomb decorative panels, inspired by rail transit decoration, which fully embodies the concept of industrialization.

Honeycomb aluminum panel function

1. Large surface and high level: The surface size of honeycomb aluminum plate can reach 1500mm×5000mm, and it can maintain excellent flatness.

2. Light weight: The weight of the honeycomb aluminum panel is only 5~5.5kg/m2, which greatly reduces the load-bearing load of the building.

3. High strength: it is not easy to deform and can meet the wind resistance requirements of super high-rise buildings.

4. Customization: The size, shape, paint surface and color of the honeycomb aluminum plate can be customized according to customer needs.

5. Easy to install: It can be installed in any order, and each wall panel can be disassembled and replaced separately, which improves the flexibility of installation and maintenance and reduces costs.

6. Box structure: The honeycomb aluminum panel is a box structure with good air tightness on the peripheral edge, which improves the safety and service life of the honeycomb aluminum panel.

7. Free welding and no nails: When installing the base and surface layers of honeycomb aluminum panels, use corner codes and screw connections to avoid frame welding, and the surface layer is installed without nails, clean and tidy.

Use aluminum composite honeycomb sheet

Honeycomb aluminum panels are high-end products derived from aerospace materials used in civil product technology. Its panels can be diversified, such as solid wood, aluminum board, gypsum board, fireproof board, MDF, natural marble materials, etc., currently used in the following aspects: architectural curtain wall decoration, ceiling ceilings, furniture honeycomb panels, partitions, elevator projects, railways transportation. △Honeycomb aluminum plate finished product

Honeycomb aluminum base installation

Aluminum honeycomb panel completes the base layer and surface layer to the on-site packaging situation

(1) Installation of longitudinal steel frame of aluminum honeycomb panel

Strictly follow the numbers and spacing on the design drawings, install the longitudinal steel frame in turn, connect the corners and the longitudinal steel frame with the rear end screws, and fix it on the wall.

(2) Aluminum honeycomb beam installation

According to the drawing number and size, install the beam; the beam is opened in advance to avoid opening on site, and the accuracy of the longitudinal steel frame installation is required.

Each basic skeleton has detailed node mapping for workers to better install.

(3) Aluminum honeycomb beam installation

The rubber pad restrains the aluminum honeycomb panel and at the same time acts as a shock absorber. The backcourt opening is required to ensure the accuracy of the longitudinal frame installation.

With aluminum buckle

When workers install screws, the reserved holes in the aluminum profile of the beam can prevent the deviation of the screws, which will affect the flatness of the finished honeycomb aluminum panel. At the same time, the screws are installed near the skeleton to improve the installation strength and stability.

Honeycomb aluminum standard board installation

(1) Aluminum honeycomb decorative board veneer installation

The fasteners are directly connected to the aluminum honeycomb panel and fixed to the beam during installation. First, place a single aluminum top plate at the designated position, then snap the honeycomb aluminum plate into the beam and fine-tune the slats.

The edge of the aluminum honeycomb panel is fixed on the beam by galvanized screws. When the special-shaped board is installed and the board cannot be fixed firmly, the edge of the aluminum honeycomb board can be fixed to the beam by galvanized screws to strengthen the connection.

After installation, the height of the aluminum honeycomb panel can be adjusted by the top screws (adjustment fasteners on the top of each honeycomb aluminum panel).

(2) Installation sequence of aluminum honeycomb panel specification board

On the same wall, strictly follow the drawing sequence, starting from the starting block, and after the installation is complete, adjust the joints.

Honeycomb aluminum door installation

(1) Grounding slot installation

(2)Hidden door aluminum honeycomb decoration installation→The aluminum honeycomb decoration is installed on the door above the door and the door leaf is connected to the side panel.

Aluminum honeycomb decoration installation for urinals

(1) Approve the position and size of the opening of the urinal, and accurately open the opening

(2) Install the urinal baffle

The embedded steel plate in the baffle is installed in the same way as the specification plate.

(3) Install urinal aluminum honeycomb decoration

The urinal is installed on two boards. It is necessary to approve the location and size of the urinal opening and open the hole on site to ensure the accuracy of the installation.

Bathroom cubic aluminum honeycomb panel installation

(1) Embedded component installation

The embedded parts are divided into horizontal limit parts and vertical fixed parts, which are connected with the longitudinal frame by galvanized screws.

(2) Install the partitions to install the partitions. After installing the partition in place, fix the aluminum plate and the insert with zinc-plated screws.

(3) Crossbar connection, fixed foot

After installing the partitions, use ordinary crosspieces to connect the partitions to the wall panels at both ends for reinforcement; fix the feet to fix the partitions. After the partition is installed, the steel frame is connected to the aluminum top seat insert plate through the corner code, so that the partition is fixed on multiple points.

(1) Approve the opening position and size of the toilet, and open it accurately

Before installation, the toilet accessories should be buried in advance, and the position and size of the toilet opening should be approved. The holes should be opened on site to ensure installation accuracy.

(2) After installing the toilet, honeycomb aluminum plate

After installing the toilet insert, the aluminum honeycomb decorative panel of the toilet is connected by Velcro.

(3) Install the cover

First install the fixed connector, then install the beam, and finally insert the cover and connect with Velcro. The installation is complete.

Construction comparative analysis

Comparative analysis of the dry hanging construction of the finished aluminum honeycomb panel in the bathroom and the traditional wet operation

1. Adopting the dry hanging process of finished aluminum honeycomb decorative panels, from the basic frame to the back surface layer production, compared with the traditional wet operation, the degree of industrialization is higher.

2. Adopt the dry hanging process of finished aluminum honeycomb decorative panels. It is not easy to produce deviations in the production process, and can be processed through modularization. Compared with traditional wet work, it can reflect the concept of standardization.

3. Dry-hanging process of finished aluminum honeycomb decorative board is adopted. Under the same conditions, fewer working hours can shorten the construction period. Compared with traditional wet work, it can better embody the concept of assembly.

4. The finished aluminum honeycomb panel can be sized and processed to produce large-area and special-shaped panels. The length and size can be adjusted according to site conditions. Compared with the traditional wet operation, the construction difficulty will be greatly reduced.

5. Adopting the dry hanging process of finished aluminum honeycomb decorative board, through pure mechanical connection, no welding is needed, and the construction is more convenient compared with the traditional wet work.

6. The finished aluminum honeycomb decoration is light in weight, especially in high-rise and super high-rise buildings, which can significantly reduce the structural weight, and compared with the traditional wet work, the impact on the structural load is minimized.