Common brushed aluminum

Common brushed aluminum can be divided into brushed aluminum plate, brushed aluminum coil and brushed aluminum foil

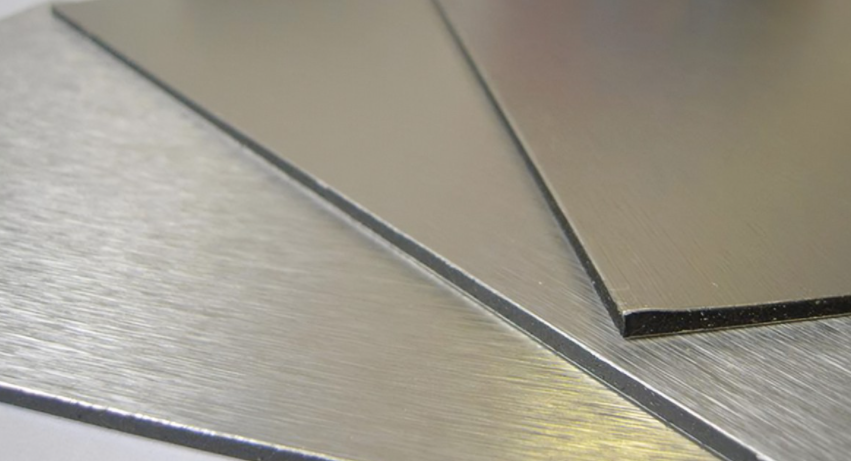

Ⅰ: brushed aluminum plate

Ⅰ-a: List of brushed aluminum sheets

| Equivalent name | Toothbrush bristle aluminum plate, hairline aluminum plate | |||

|---|---|---|---|---|

| color | silver, gold, bronze, green, stainless steel, blue, red, copper, black, pink, brass, bronze, cycads, matte, etc. | |||

| Types of brushed aluminum sheets | Drawing can be made into straight grains, cross grains, random grains, threads, corrugations and swirls according to decorative needs: | |||

| thickness | Common thickness: 1mm (thin), 6mm, etc. | |||

| surface treatment | Anodizing etc. | |||

| application | Brushed aluminum panels are widely used in brushed aluminum-plastic panels, fireproof panels, aluminum frames, boutique cabinets, boutique doors and windows, decorative panels, signs, lighting, indoor and outdoor decoration, household appliances, luggage, gifts, furniture, consumer electronics and other fields. | |||

Ⅰ-b:Features of brushed aluminum sheet

1. Good tolerance: whether indoor or outdoor, the long-term use of aluminum wire drawing does not change color, does not corrode, does not oxidize, and does not rust

2. Strong metallic luster: retains the original metallic luster of the brushed aluminum plate, highlighting the modern metallic feel

3.Good processability: the aluminum plate has strong decorative wire drawing, moderate hardness, and can be easily bent and formed

4. Strong stain resistance: the brushed aluminum plate leaves no fingerprints, no smudges, easy to clean, and no corrosion spots.

5. High fire resistance: The brushed aluminum plate is a pure metal product, which does not burn at a high temperature of 600 degrees, does not produce toxic gases, and meets the requirements of fire protection and environmental protection.

Ⅰ-c:What are the common alloy types of brushed aluminum sheets?

| 1××× series pure aluminum plate | the commonly used codes of pure aluminum plate series are 1050, 1060 and 1100.The purity can reach more than 99.00%. | |||

|---|---|---|---|---|

| 2××× series alloy aluminum plate | The 2××× series aluminum plate is characterized by high hardness, among which the original copper content is the highest, about 3-5%. 2××× series aluminum sheets belong to aviation aluminum materials, which are not often used in conventional industries. | |||

| 3××× series alloy aluminum plate | mainly represent 3003 aluminum plate, 3004 aluminum plate and 3A21 aluminum plate. Mainly composed of manganese element. It is routinely used in humid environments such as air conditioners, refrigerators, and car bottoms. The price is higher than that of the 1××× series. | |||

| 4××× series alloy aluminum plate | the representative is 4A01. It belongs to the series with high silicon content. Usually the silicon content is between 4.5-6.0%. It belongs to building materials, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance. | |||

| 5××× series alloy aluminum plate | represents 5052 aluminum plate, 5005 aluminum plate, 5083 aluminum plate, 5A05 aluminum plate series. Also known as aluminum-magnesium alloy.It is often used in aviation, such as aircraft fuel tanks. It is also widely used in conventional industries. | |||

| 6××× series alloy aluminum plate | 6061 is a cold-treated aluminum forging product, which is suitable for applications with high requirements on corrosion resistance and oxidation resistance. | |||

Ⅰ-d:Types of brushed aluminum sheets

Drawing can be made into straight grain, cross grain, random grain, thread, corrugation and spiral pattern according to decorative needs.

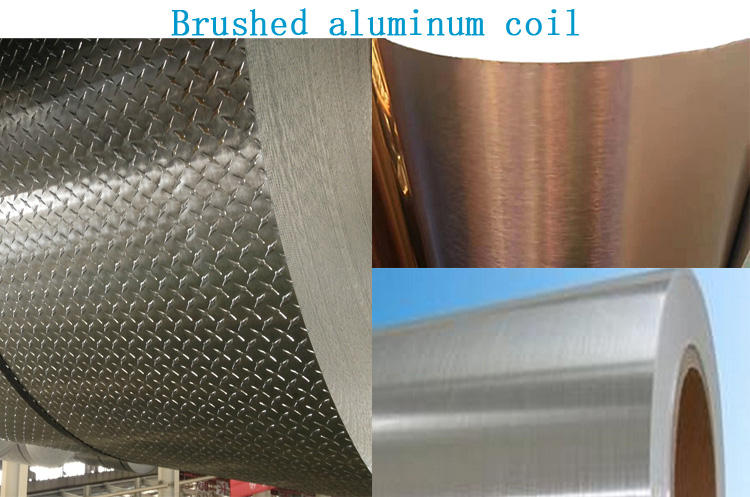

Ⅱ:Brushed aluminum coil

Brushed aluminum coil specification:

| Aluminum Alloy | AA1100; AA3003 | |||

|---|---|---|---|---|

| Coil thickness | 0.15mm, 0.21mm, 0.30mm, 0.40mm, 0.50mm | |||

| Coil width | 1240mm, 1270mm, 1520mm, | |||

| Diameter | 405mm, 505mm | |||

| Coil weight | 2.5 to 3.0 tons per coil | |||

| Color | Silver & gold | |||

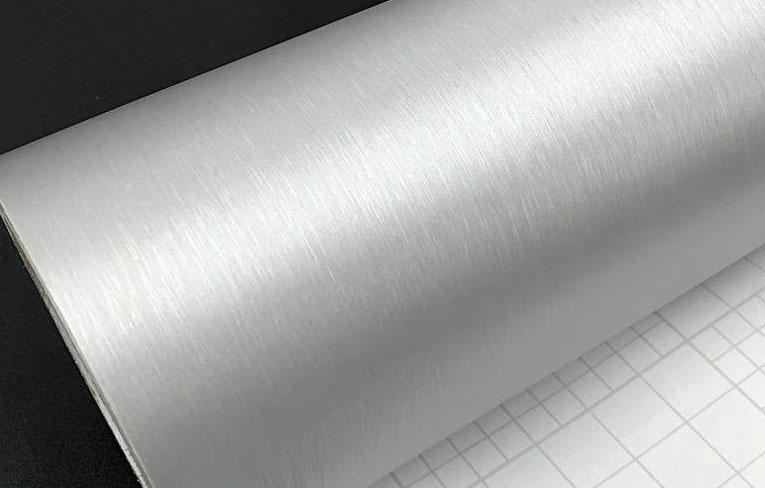

Ⅲ:Brushed aluminum foil

Brushed aluminum foil is a commonly requested aluminum surface. It's versatility makes it a popular choice allowing for custom color, gloss, and texture. Aside from these choices there are also different grain structures to choose from.

Ⅲ-a: Features

- Anti-corrosion

- Durable

- Light character and better form ability

- Anti scratch with high surface hardness

- Finger print resistance and very easy to clean and process

- Heat/ Fire resistance

- Color rich and colorful

| Name | Alloy | Temper | Widthmm | Thickness mm | |

| Aluminum foil for flexible packing | 8011 1235 | O | 300--700 | 0.009~0.05 | |

| Colored aluminum alloy foil for cable wrap | 8011 | O | 300--700 | 0.01--0.015 | |

| Aluminum foil for heat preservation and insulation | 8011 | O | 300--700 | 0.01--0.016 | |

| Aluminum foil for adhesive tape | 1235 8011 | O | 400--700 | 0.03--0.05 | |

| colored cooking Aluminum foil | 1235 8011 | O | 300-700 | 0.015 ~ 0.1 | |

| cooking Aluminum afoil for Food stuffs | 1235 8011 | O | 300-700 | 0.009 ~ 0.02 | |

| Aluminum alloy foil for tube | 1235 8011 | O | 300-700 | 0.009-0.01 | |

| Aluminum and aluminum alloy foil for hot seal purpose | 8011 | O | 400--500 | 0.009--0.018 | |

Ⅲ-b:Application:

- As HPL,ACP(Aluminum Composite panel),Fireproof board,LED lights.

- To make aluminum frame,integrated ceiling,boutique windows & doors,Veneered panel

- Widely used in making baffle plate,sign board,lighting lamp, decoration materials

- Widely used in living things,including household cupboard,Luggage,gifts,wardrobe,furniture,Smoking machine panel,Jewelry box ,photo frame,mobile phone shell,computer panel and so on.

Huawei Aluminum Quotation

| Date | LME | LME Weekly Price | 2023-04 LME Average | 2023-04 SMM Average |

| 2023-05-03 | 2330$ | 2333.3$ | 2341.00$ | 2712.08$ |

| 2023-05-02 | 2353$ | |||

| 2023-04-28 | 2342$ | |||

| 2023-04-27 | 2302$ | |||

| 2023-04-26 | 2339.5$ | |||

| Notes

1. Prices are updated at 10:00 am on weekdays. |

||||