Huawei aluminum: Global Player in the Aluminum Foil Manufacturing Market

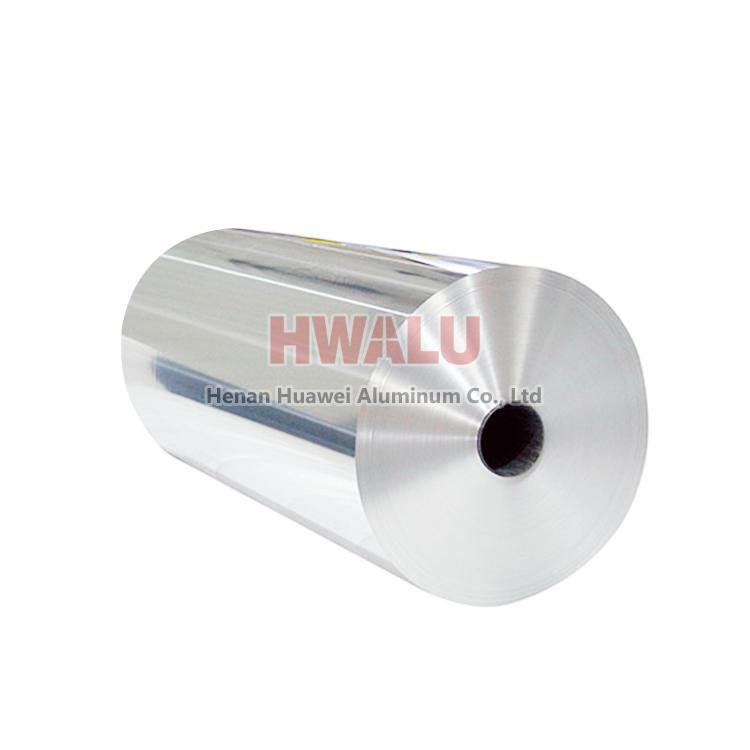

Huawei aluminum provides custom thickness aluminum foil

Different thicknesses of aluminum foil have different uses, Huawei aluminum provides different thicknesses of aluminum foil, which can be customized according to your requirements.

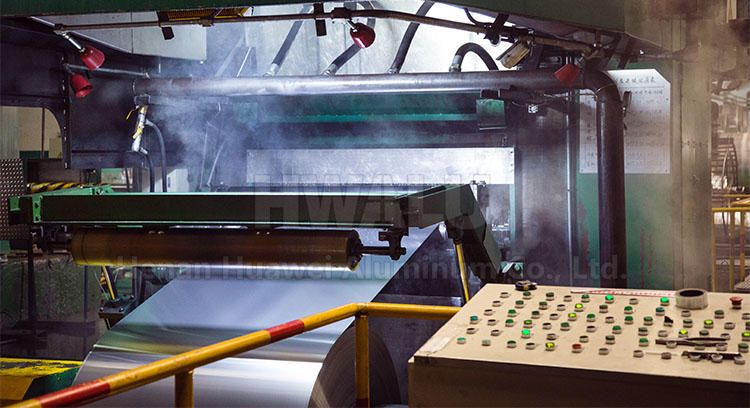

Aluminum foil production process

Aluminum Foil Thickness For Different Application

| Applications | Alloy State | Typical Thickness(Mm) | Processing Methods | End Use |

| smoke foil | 1235-O、8079-O | 0.006~0.007 | Composite paper, coloring, printing, etc. | Used in cigarette packaging after lining, printing or painting. |

| Flexible packaging foil | 8079-O、1235-O | 0.006~0.009 | Composite paper, plastic film embossing, coloring, printing, etc. | Candy, milk and dairy products, powdered food, beverages, tea, bread, various snacks, etc. |

| Cardboard foil | 1235-O, 8079-O | 0.006 | aluminum plastic paper composite. | for barrier and aesthetics. |

| Aseptic bag | 1235-O、8111-O、8079-O | 0.0063, 0.00635 | aluminum plastic paper composite, printing | As a barrier material, it is made into a rectangular carton package with a straw hole (when drinking soda), such as: Tetra Pak, Combibloc, etc. |

| Household foil | 8011-O | 0.008~0.02 | small roll | used for food preservation, barbecue, aviation, hotel catering and kitchen cleaning. |

| Hose foil | 8011-O、1060-O | 0.012-0.02 | composite, printing, etc. | After composite printing with PE, it is used to process the packaging of cream products such as toothpaste, ointment, and cosmetics. |

How to control the rolling thickness of aluminum foil?

Aluminum foil is rolled without rolls, and the rolls are always in a state of elastic flattening.

During the rolling process, the thickness of the foil can be controlled by adjusting the rolling force, rolling speed and controlling the tension.

In the process of rough rolling, the thickness of the foil is controlled by the rolling force; in the process of finishing rolling, the thickness of the foil decreases with the increase of the rolling speed; The conditional yield strength is σ0.2~0.4

During low-speed rolling, heavy oil or thin oil is often added to the lubricating oil to adjust the rolling thickness of the aluminum foil. Lubricants and roll conditions have a very important influence on foil quality.

custom thickness aluminum foil

Aluminum foil blank

Aluminum foil blank comes from cold rolled aluminum coil, which is generally pre annealed at 340 ~ 480 ℃, and its thickness is 0.4 ~ 0.7mm.

During rolling, the pass deformation rate is about 50%, and the total deformation rate can reach more than 95%.

Alloys of custom thickness aluminum foil

We produce aluminum foil in a wide variety of alloys. Among them, the more popular alloys are

1100, 1235, 3003, 8011, 8021, 8079, etc.

custom thickness aluminum foil

Huawei Aluminum Quotation

| Date | LME | LME Weekly Price | 2023-04 LME Average | 2023-04 SMM Average |

| 2023-05-03 | 2330$ | 2333.3$ | 2341.00$ | 2712.08$ |

| 2023-05-02 | 2353$ | |||

| 2023-04-28 | 2342$ | |||

| 2023-04-27 | 2302$ | |||

| 2023-04-26 | 2339.5$ | |||

| Notes

1. Prices are updated at 10:00 am on weekdays. |

||||