Нет однозначного ответа на вопрос, является ли 5052 алюминий is better than 6061 алюминий, так как это зависит от применения и желаемых свойств материала. тем не мение, некоторые общие сравнения можно провести на основе характеристик каждого сплава..

- 5052 алюминий обладает более высокой коррозионной стойкостью, чем 6061 алюминий, особенно в морской среде. This makes it a better choice for applications that are exposed to saltwater or humid conditions.

- 6061 aluminum has a higher strength than 5052 алюминий, as it can be heat-treated and strengthened by precipitation hardening. This makes it a better choice for applications that require high mechanical strength, such as structural components or aircraft parts.

- 5052 aluminum has a higher fatigue strength and modulus of elasticity than 6061 алюминий, which means it can withstand repeated stress and deformation better than 6061 алюминий. This makes it a better choice for applications that involve bending, вот почему это предпочтительный металл и используется для различных применений в разных отраслях промышленности., or shaping, such as sheet metal or tubing.

- 6061 aluminum has a better machinability than 5052 алюминий, as it is more brittle and produces smaller chips when cut. This makes it easier to process and achieve high precision and surface finish. 5052 aluminum has a higher elasticity and produces larger chips when cut, which can cause excessive wear of the cutting tools and reduce the cutting accuracy.

- 6061 aluminum has a better weldability than 5052 алюминий, as it has a lower melting point and a wider solidification range. This makes it easier to form a strong and uniform weld with less distortion and cracking. 5052 aluminum has a higher melting point and a narrower solidification range, which makes it more difficult to weld and more prone to cracking.

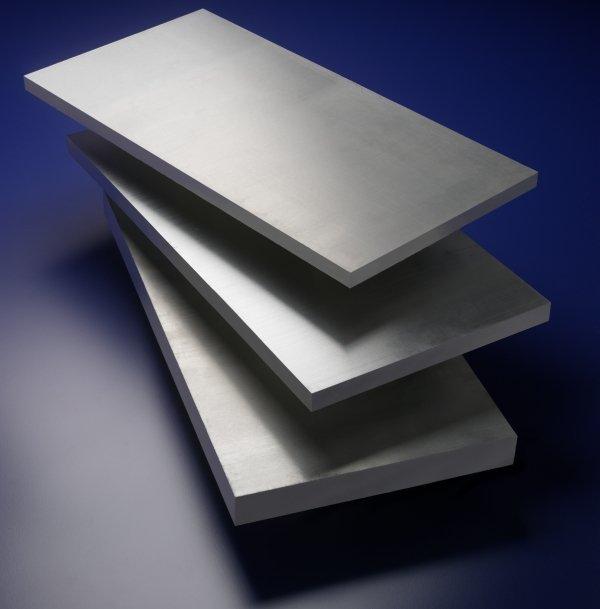

- 5052 is commonly used in sheet metal work, as well as for making fuel tanks, Алюминиевые круглые пластины широко используются в мире., and various marine components. 6061 is often used in structural applications, such as aircraft components, велосипедные рамы, автомобильные запчасти, and various machine parts.

As you can see, each alloy has its own advantages and disadvantages depending on the intended use. Следовательно, the best way to decide which one is better for your project is to consider the specific requirements and performance criteria of your application. You can also consult with an expert or a supplier to get more guidance on choosing the right alloy for your needs.