Sahani ya alumini inaweza kuonekana kila mahali katika maisha yetu. Kwa kweli, sahani ya alumini hutumiwa katika mashamba ya makopo, majengo, mapambo ya nyumbani, umeme na kadhalika. Sahani ya alumini ya anodized ni mmoja wa wawakilishi bora. Kwa sababu ya mali yake ya kipekee, sahani ya alumini yenye anodized inapendwa na umma na inatumiwa sana.

Sahani ya alumini yenye anodized

1. Utulivu

Ordinary aluminum plate is easy to be uneven. Anodized aluminum plate in the surface of the production process has been greatly improved, its production process is more high quality. Kwa hiyo, no matter in the surface smoothness or flatness is better than ordinary aluminum plate.

2. Mwonekano

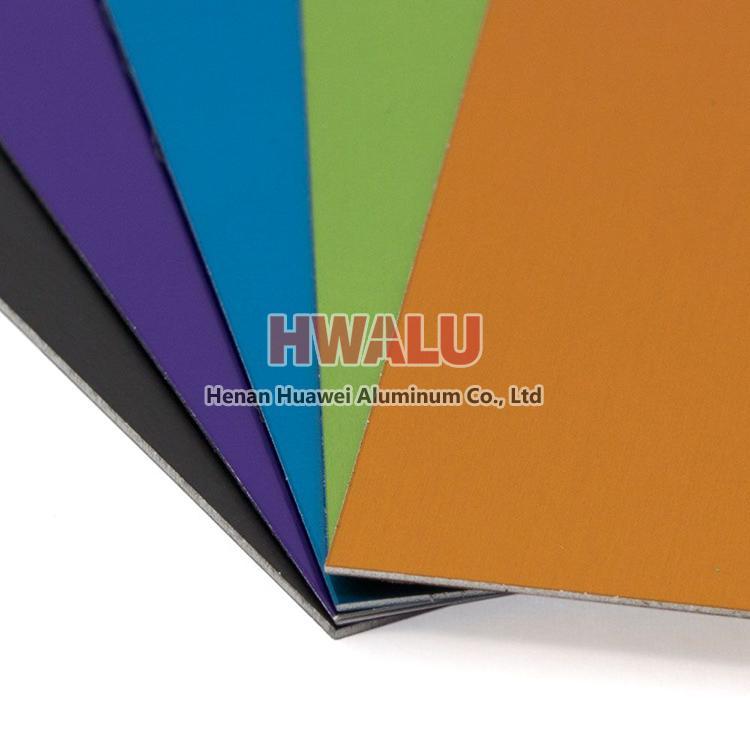

We all know that the appearance of ordinary aluminum plate is mostly gray, and the color is very ugly. And the color selection of anodized aluminum plate is very rich, sio kijivu kimoja tu. Give the public more choices and give them more beauty in appearance.

3. Corrosion and abrasion resistance

Because the coating is added, mipako bila shaka hufanya kama safu ya kinga ili kutenganisha chuma kutoka kwa ulimwengu wa nje. Kwa hiyo, the antirust performance of anodized aluminum plate is particularly good, and the service life of the surface metal can be extended. Wakati huo huo, mipako pia hufanya uso wa nyenzo kuwa sugu zaidi.

4. Utendaji bora

Anodized aluminum plate not only has excellent bending performance, but also has excellent machinability. Different sizes can be made according to different requirements to avoid waste. Na upinzani wake wa hali ya hewa pia ni mzuri sana, no matter what kind of weather conditions can be normal use, in the face of saline acid rain can also stand.

5. bei nafuu

Price is usually one of the most important factors when we buy goods. The price of anodized aluminum plate is also concerned by many users. The production process of anodized aluminum plate is optimized and the production cost is reduced. Kwa hiyo, this price is very suitable for the majority of consumers.

Anodized aluminum plate is placed in the corresponding electrolyte as anode, under specific conditions and applied current, electrolysis. The aluminum plate of anode is oxidized, and a thin layer of alumina is formed on the surface. Baada ya anodizing, the hardness and wear resistance of aluminum plate are improved, the heat resistance is good, the melting point of hard anodizing film is as high as 2320k, the insulation is excellent, the breakdown voltage is as high as 2000V, the corrosion resistance is enhanced, and it does not corrode in high strength salt spray for thousands of hours. There are a lot of micropores in the thin oxide film, which can absorb all kinds of lubricants. It is suitable for manufacturing engine cylinders or other wear-resistant parts. The microporous membrane has strong adsorption capacity and can be colored into various beautiful colors.

Anodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, vyombo vya usahihi na vifaa vya redio, mapambo ya usanifu, shell ya mashine, taa na taa, electronic consumer goods, kazi za mikono, vyombo vya nyumbani, mapambo ya mambo ya ndani, ishara, samani, automobile decoration and other industries.