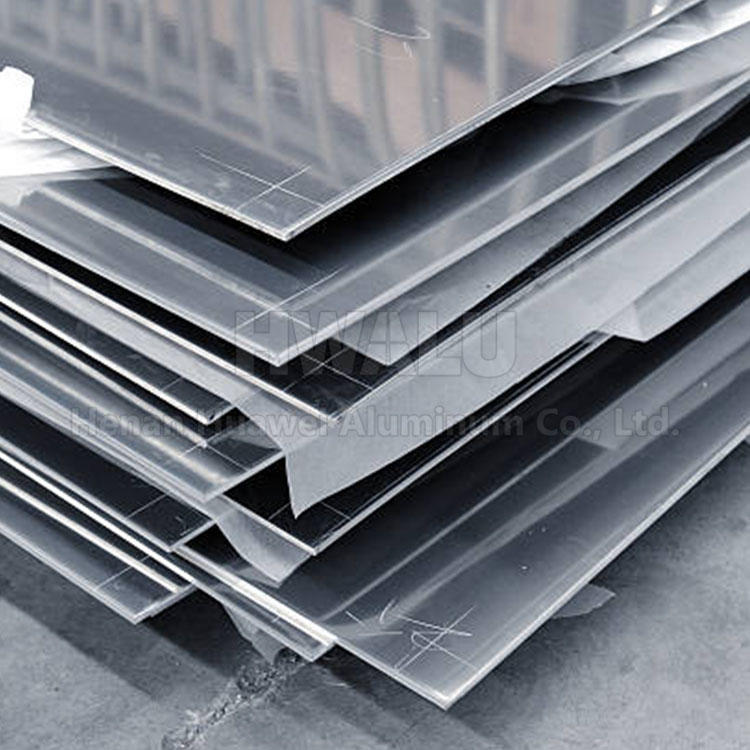

5251 Aluminium sheet Overview

5251 is a medium-strength metal known for its ductility and formability

This grade of Aluminium alloy is best known as a metal that can harden rapidly and is weldable easily.

The 5251 alloy is also popular because of its high resistance to corrosion and is commonly used in marine, coastal environments.

5251 Aluminium sheet Tempering

5251 alloy aluminum sheet can be provided in different tempers to achieve specific mechanical properties and characteristics. The common alloys include:

H22 - Work hardened and partially annealed to a quarter hard state

H24 - Work hardened and partially annealed to a half hard state

H26 - Work hardened and partially annealed to a three-quarter hard state

O – Wrought and fully annealed

The choice of temper for 5251 aluminum alloy, or any aluminum alloy, depends on the specific requirements of your application. If you need a balance of strength and workability, H22 is a common choice. However, if higher strength is required at the expense of some formability, you might opt for a higher number, like H32 or H34. Conversely, if formability is more critical, you might consider a lower number or the "O" temper. It's essential to consult with aluminum suppliers or manufacturers to select the right temper for your specific application.

5251 Aluminium sheet

5251 Aluminium sheet Chemical Composition

| Cu | Mn | Si | Fe | Mg | Cr | Zn | Ti | Ai | |

| Min | 0.15 Typical | 0.1 | 0.2 | 0.5 Typical | 1.7 | 0.15 Typical | 0.15 Typical | 0.15 Typical | Balance |

| Max | 0.5 | 0.6 | 2.4 |

5251 Aluminium sheet Welding

Grade 5251 Aluminium alloy is a good weldable alloy.

When welding this alloy to itself it is recommended that use filler wire is 5356.

Filler wire 5356 is also recommended if you are welding 5251 alloys to an alloy of the 6000 series, 7000 series and the majority of 5000 series.

If you are welding either 5251 to 5005 or 5020 or an alloy of the 1000 series and the 3000 series of alloys then we suggest you use filler wire 4043.

Mechanical Properties of Aluminium Alloy 5251

The following parameter table refers to the authoritative website AZOM

Mechanical properties for aluminium alloy 5251 Soft O

| BS EN 485-2:2008 Sheet and Plate 0.2mm to 50.00mm |

|

|---|---|

| Property | Value |

| Proof Stress | 60 Min MPa |

| Tensile Strength | 160 - 200 MPa |

| Hardness Brinell | 44 HB |

*Properties above are for material in the Soft O condition

Mechanical properties for aluminium alloy 5251 H22

| BS EN 485-2:2008 Sheet and Plate 0.2mm to 25mm |

|

|---|---|

| Property | Value |

| Proof Stress | 120 Min MPa |

| Tensile Strength | 190 - 230 MPa |

| Hardness Brinell | 56 HB |

*Properties above are for material in the H22 condition

Mechanical properties for aluminium alloy 5251 H24

| BS EN 485-2:2008 Sheet & Plate 0.2mm to 12.5mm |

|

|---|---|

| Property | Value |

| Proof Stress | 140 Min MPa |

| Tensile Strength | 210 - 250 MPa |

| Hardness Brinell | 62 HB |

*Properties above are for material in the H24 condition

Mechanical properties for aluminium alloy 5251 H26

| BS EN 485-2:2008 Sheet and Plate 0.2mm to 4mm |

|

|---|---|

| Property | Value |

| Proof Stress | 170 Min MPa |

| Tensile Strength | 230 - 270 MPa |

| Hardness Brinell | 69 HB |

*Properties above are for material in the H26 condition

Physical Properties of Aluminium Alloy 5251

Physical properties for aluminium alloy 5251

| Property | Value |

|---|---|

| Density | 2.69 g/cm3 |

| Melting Point | 625°C |

| Modulus of Elasticity | 70 GPa |

| Electrical Resistivity | 0.44 x 10-6 Ω.m |

| Thermal Conductivity | 134 W/m.K |

| Thermal Expansion | 25 x 10-6/K |

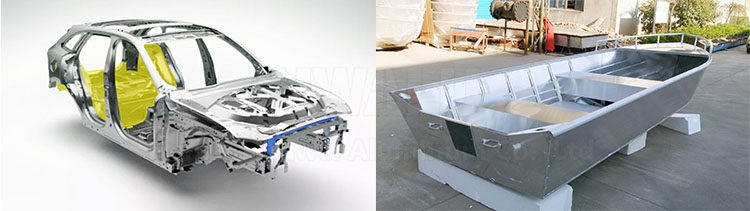

5251 alloy aluminum sheet/plate Applications

When it comes to aluminum sheet and plate products made from the 5251 alloy, here are some key features and potential applications:

- Boats

- Panelling and pressings

- Marine structures

- Aircraft parts

- Vehicle panels

- Furniture tubing

- Silos

- Containers

Application of 5251 aluminum sheet

Huawei Aluminum Quotation

| Date | LME | LME Weekly Price | 2023-04 LME Average | 2023-04 SMM Average |

| 2023-05-03 | 2330$ | 2333.3$ | 2341.00$ | 2712.08$ |

| 2023-05-02 | 2353$ | |||

| 2023-04-28 | 2342$ | |||

| 2023-04-27 | 2302$ | |||

| 2023-04-26 | 2339.5$ | |||

| Notes

1. Prices are updated at 10:00 am on weekdays. |

||||