Ⅰ: 6063 Alloy Metal Aluminum Sheet Overview

Ⅰ-a: What is 6063 aluminum sheet?

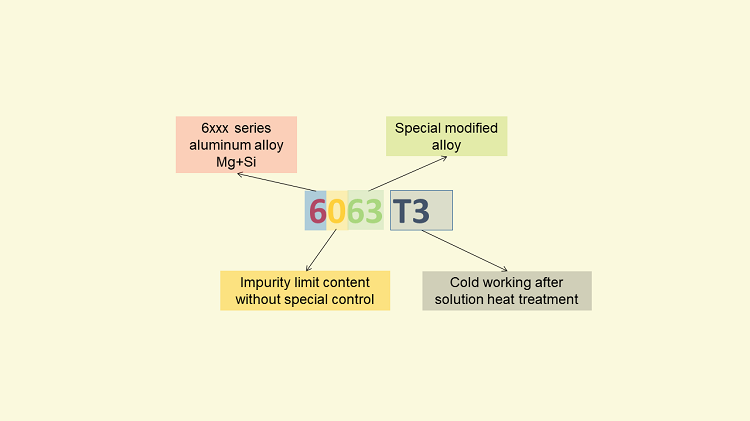

6063 aluminum alloy is Al-Mg-Si alloy, with excellent processing performance, excellent solderability, extrusion, and plating, good corrosion resistance, toughness, easy polishing, anodizing Excellent effect, is a typically extruded alloy.6061-T3 is one of the most commonly used 6000 series aluminum alloys.

6063 aluminum sheet for sale

The mean of 6063 T3 aluminum sheet temper

Ⅰ-b: Features of 6063 alloy metal aluminium sheets

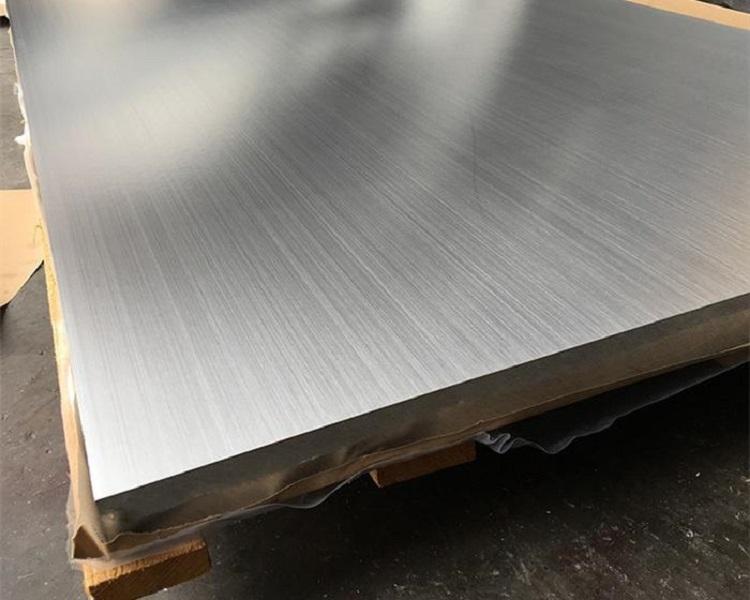

The aluminum 6063 has generally good mechanical properties and is heat treatable and highly wieldable. The material can be re-heat-treated to restore a higher temper for the whole piece. However, it has half the strength of aluminum 6061 alloys. It is typically produced with very smooth surfaces fit for anodizing

Ⅰ-c: Specifications of 6063 aluminum plates

1.Equivalent product name

Flat aluminum sheet, aluminium plain sheet, etc

2.Equivalent alloy name

a6063 aluminum sheet, 6063a aluminum sheet, aa6063 aluminum sheet, 6063aa aluminum sheet, al6063 aluminum sheet,

al6063a aluminum sheet, a 6063 aluminum sheet, aa 6063 aluminum sheet, jis a6063p aluminum sheet,

al6063 aluminum sheet class, aw6063 aluminum sheet, en6063 aluminum sheet grade, etc

3.Temper: F, O, T3, T4, T6, T651, etc

4.Thickness: 3/16 inch, 3mm, 3.3mm, 4mm, 5mm, 6mm, 10mm ( thick ), etc

5.Size ( customized to cut ): 500x1000mm ( small ), 4x8ft (standard size), 5x10 foot etc

6.Technology: hot rolled ( DC ), cold rolling ( CC ),

7.Surface treatment: anodized, mirror, color coated, etc

Ⅰ-d: Applications of 6063 aluminum sheet plate

6063 Aluminum sheet is widely used in for its good plasticity

6063 aluminum alloy is widely used in the construction of aluminum doors, windows, curtain walls, irrigation pipes, commercial vehicle floor, roof structure, PCB, vehicles, benches, duct design, CNC machining, furniture, sublimation blanks, heat sink, square cooling plate, lifts, freezer, shelves, printing, decorative hanging wall, roofing sheets, electronic components is a common aluminum alloy model. In order to ensure that doors, windows, and curtain walls have high wind pressure resistance, assembly performance, corrosion resistance and decorative performance, the comprehensive performance requirements of aluminum alloy profiles are far higher than industrial profile standards.

6063 aluminum sheet is an aluminum alloy, with magnesium and silicon as the alloying elements. It is typically produced with a very smooth surface fit for anodizing. It has generally good mechanical properties and is heat treatable and weldable. It is similar to the British aluminum alloy HE9.

6063 aluminum sheet supplier

Ⅱ: 6063 Alloy Metal Aluminum Sheet Overview

Ⅱ-a: Chemical composition of 6063 aluminum sheet

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Ni | Others | Al |

| 6063 | ≤0.60 | ≤0.35 | ≤0.1 | ≤0.9 | ≤0.1 | ≤0.1 | ≤0.25 | ≤0.1 | - | ≤0.15 | Remainder |

Ⅱ-b: 6063 aluminum sheet mechanical properties

| Temper | Tensile | Hardness | ||||

| Ultimate | Yield | Elongation | Brinell | |||

| KSI | MPA | KSI | MPA | % | ||

| T5, T52 | 27 | 186 | 21 | 145 | 12 | 60 |

| T6 | 35 | 241 | 31 | 214 | 12 | 73 |

Ⅲ: 6063 alloy metal aluminum sheet plate for shipbuilding

A ship vessel is a necessary object on the ship, its structure in order to prevent overturning strength and stability to achieve certain requirements, ship vessel structure requirements include the use of material mechanical properties, corrosion resistance, high-temperature resistance, and production process.

6063 aluminum plate hardness is high, hard resistance is strong, will not easily appear fracture phenomenon, can ensure that the liquid in the vessel safe and sound. 6063 aluminum alloy belongs to the aluminum-magnesium-silicon system alloy, is a medium-strength can be heat treatment strengthening alloy, mechanical properties are more stable, tensile strength is good, can resist external pressure, so that the vessel itself deformation degree to the minimum. So it can be used as a marine-grade aluminum sheet.

6063 aluminum hardness and 6063 aluminum alloy tensile strength can be said to determine the ship vessel pressure strength of important factors, 6063 aluminum can be processed into a variety of profiles, heat treatment, and strengthening can be obtained after good mechanical properties, physical properties, and corrosion resistance properties, used for offshore ship vessel structure material is more suitable.

6063 aluminum sheet for sale

Ⅳ: 6063 aluminum sheet surface corrosion

The behavior of 6063 aluminum alloy profile corrosion caused by silicon can be completely prevented and controlled, as long as the raw material purchase and alloy composition are effectively controlled to ensure that the ratio of magnesium to silicon is within the range of 1.3 to 1.7, and the parameters of each process are strictly controlled To avoid segregation and free of silicon, try to make silicon and magnesium form a beneficial Mg2Si strengthening phase.

If this kind of silicon corrosion point phenomenon is found, special attention should be paid to the surface treatment. In the process of degreasing and degreasing, use a weak alkaline bath as much as possible. If the conditions do not allow it, it should also be soaked in acid degreasing liquid for a period of time.

As short as possible (qualified aluminum alloy profiles are placed in acidic degreasing liquid for 20-30 minutes without problems, and problematic profiles can only be placed for 1 to 3 minutes), and the pH of the washing water should be higher (pH>4, control Cl-content), as long as possible during the alkali corrosion process, the nitric acid light solution should be used when neutralizing the light, and the oxidation treatment should be energized as soon as possible during the anodization of sulfuric acid, so that the dark gray corrosion points caused by silicon are not obvious, To meet the requirements of use.

V: Relevant grade of 6063 aluminum sheet packaging

6063 aluminum sheet of Henan Huawei Aluminum. meet the export standard. Plastic film and brown paper can be covered at customers’ needs. What’s more, a wooden case or wooden pallet is adopted to protect products from damage during delivery. There are two kinds of packaging, which are eye to wall or eye to the sky. Customers can choose either of them for their convenience. Generally speaking, there are 2 tons in one package, and loading 18-22 tons in 1×20′ container, and 20-24 tons in 1×40′ container.

6063 aluminum sheet packaging

As a China-based 6063 aluminum sheet manufacturer and supplier, we at Huawei also produce aluminum slit coil, aluminum strip, coated aluminum coil, aluminum plate, anodising aluminum sheet, embossed aluminum sheet, etc. For more detailed information, please continue browsing our website or feel free to contact us directly.

Huawei Aluminum Quotation

| Date | LME | LME Weekly Price | 2023-04 LME Average | 2023-04 SMM Average |

| 2023-05-03 | 2330$ | 2333.3$ | 2341.00$ | 2712.08$ |

| 2023-05-02 | 2353$ | |||

| 2023-04-28 | 2342$ | |||

| 2023-04-27 | 2302$ | |||

| 2023-04-26 | 2339.5$ | |||

| Notes

1. Prices are updated at 10:00 am on weekdays. |

||||