1. Introduction

Aluminum electrolytic capacitors are currently a wide variety of capacitors in addition to ceramic capacitors. Therefore, as a hardware engineer, you must master its characteristics.

Based on our own experience, we have summarized this document for the hardware design needs and difficulties by consulting various materials. By writing documents, the purpose is to make one's knowledge more systematic, learn the new through reviewing the past, and also hope that it will be helpful to the readers, so that everyone can learn and make progress together.

2. Overview of aluminum electrolytic capacitors

2.1, the basic model

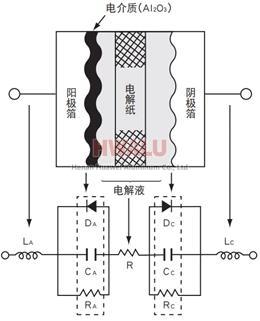

Capacitors are passive devices. Among various capacitors, aluminum electrolytic capacitors have a larger CV value and a cheaper price when the same size is compared with other capacitors. The basic model of the capacitor is shown in the figure.

The electrostatic capacity calculation formula is as follows:

Among them, is the dielectric constant, S is the surface area of the two pole plates facing each other, and d is the distance between the two pole plates (the thickness of the dielectric).

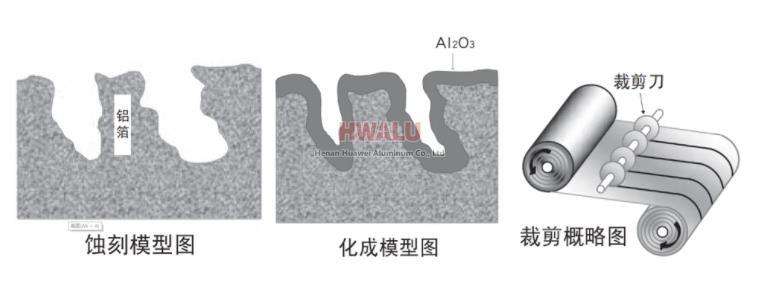

It can be seen from the formula that the electrostatic capacity is proportional to the dielectric constant, and the surface area of the plate is inversely proportional to the distance between the two plates. As the dielectric constant of the dielectric oxide film (Al2O3) of aluminum electrolytic capacitors is usually 8~10, this value is generally not larger than other types of capacitors, but by etching the aluminum foil to enlarge the surface area, and using electrochemical treatment to get thinner The more voltage-resistant oxidized dielectric layer allows aluminum electrolytic capacitors to achieve a larger CV value per unit area than other capacitors.

The main components of aluminum electrolytic capacitors are as follows:

Anode---aluminum foil

Dielectric—Oxide film (Al2O3) formed on the surface of anode aluminum foil

Cathode—The real cathode is electrolyte

Other components include electrolytic paper impregnated with electrolyte, and cathode foil connected to the electrolyte. In summary, aluminum electrolytic capacitors are components with polar asymmetric structure. Both electrodes use anode aluminum foil is a bipolar (non-polar) capacitor.

2.2. Basic structure

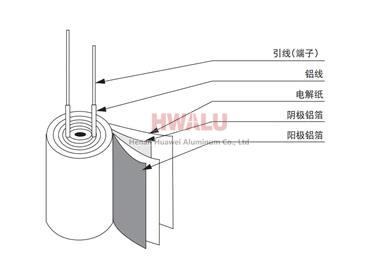

The structure of the aluminum electrolytic capacitor element is shown in the figure. It is made up of anode foil, electrolytic paper, cathode foil and terminals (internal and external terminals) wound together, impregnated with electrolyte, and packed into an aluminum case, and then sealed with rubber.

2.3, the characteristics of the material

Capacitor aluminum foil is the main material of aluminum electrolytic capacitors. The aluminum foil is set as the anode. After electricity is energized in the electrolyte, an oxide film (Al2O3) will be formed on the surface of the aluminum foil. This oxide film functions as a dielectric.

The aluminum foil after the oxide film is formed is a metal with rectifying properties in the electrolyte, like a diode, which is called a valve metal.

First, in order to expand the surface area, the aluminum foil material is placed in an aqueous chloride solution for electrochemical etching. Then, after applying a voltage higher than the rated voltage in the ammonium borate solution, a dielectric oxide layer (Al2O3) is formed on the surface of the aluminum foil. This dielectric layer is a very thin and dense oxide film, about 1.1~1.5nm/V, and the insulation resistance is about It is 10^8~10^9Ω/m. The thickness of the oxide layer is proportional to the withstand voltage.

Like the anode foil, the cathode aluminum foil also has an etching process, but there is no oxidation process. Therefore, there is only a small amount of natural oxidation (Al2O3) on the surface of the cathode aluminum foil, and the voltage it can withstand is only about 0.5V.

Electrolyte

The electrolyte is a liquid that conducts electricity by ions. It is a cathode in the true sense and serves as a dielectric layer that connects the surface of the anode aluminum foil. The cathode aluminum foil, like the collector, acts as a connection between the real cathode and the internal circuit. Electrolyte is the key material that determines the characteristics of capacitors (temperature characteristics, frequency characteristics, service life, etc.).

Electrolytic paper

Electrolytic paper mainly plays a role in balancing the distribution of electrolyte and keeping the gap between the cathode foil and the anode foil.

2.4. Production process

Etching (expanding surface area)

The effect of etching is to enlarge the surface area of the aluminum foil. Etching is an electrochemical process in which alternating or direct current is applied to a chloride solution.

Formation (formation of dielectric layer)

Formation is the process of forming a dielectric layer (Al2O3) on the surface of the anode aluminum foil. Generally, the formed aluminum foil is used as an anode.

Crop

According to the size requirements of different products, cut the aluminum foil (cathode foil and anode foil) and electrolytic paper to the required size.

Winding

Insert electrolytic paper between the cathode foil and the anode foil, and then wind it into a cylindrical shape. In the winding process, the cathode foil and the anode foil are connected to the terminals.

Impregnation

Impregnation is the process of immersing the element into the electrolyte. The electrolyte can further repair the dielectric layer.

seal

Sealing is the process of putting the element into the aluminum shell and then sealing it with a sealing material (rubber, rubber cover, etc.).

Aging (reformed into)

Aging is the process of applying voltage to the sealed capacitor at a high temperature. This process can repair some damage to the dielectric layer during the cutting and winding process.

Full inspection, packaging

After aging, all products will be checked for electrical characteristics. And for terminal processing, braiding and so on. Pack it.

3. Basic characteristics

3.1, electrostatic capacity

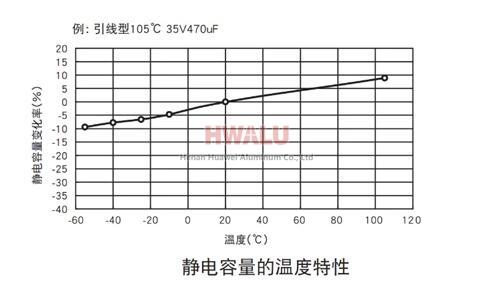

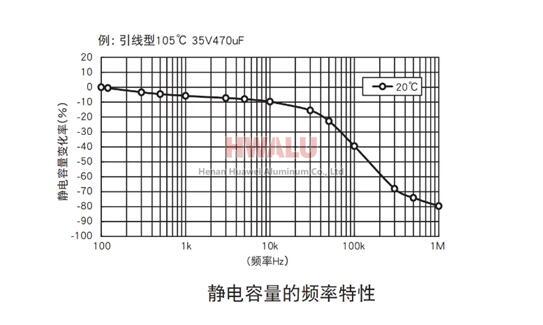

The greater the surface area of the electrode, the greater the capacity (the ability to store charge). The capacitance value of aluminum electrolytic capacitor is the value tested under the condition of 20℃, 120Hz/0.5V alternating current.

As the temperature increases, the capacity increases; as the temperature decreases, the capacity decreases.

The higher the frequency, the smaller the capacity; the lower the frequency, the larger the capacity.

3.2, loss angle

The equivalent circuit of the electrolytic capacitor is shown in the figure above (ignoring the insulation resistance). When the frequency is 120Hz (the nominal loss angle of the general capacitor is measured at this frequency), the frequency is very low relative to the equivalent series inductance L, so it can be ignored L, the loss angle model is as follows:

The loss angle formula can be obtained:

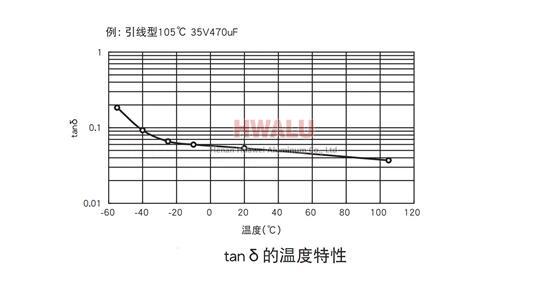

The relationship between loss angle and temperature is shown in the figure below. The higher the temperature, the smaller the loss angle.

At low temperatures, it can be seen that the loss angle becomes much larger. It is 0.05 at 20°C and 0.09 at -40°C. According to the formula, the ESR has increased by nearly double.

3.3, leakage current

Leakage current is one of the characteristics of aluminum electrolytic capacitors. When a DC voltage is applied, the dielectric oxide layer allows a small current to pass. This part of the small current is called leakage current. The ideal capacitor will not produce leakage current (unlike the charging current, this current will continue to exist even if the voltage is constant).

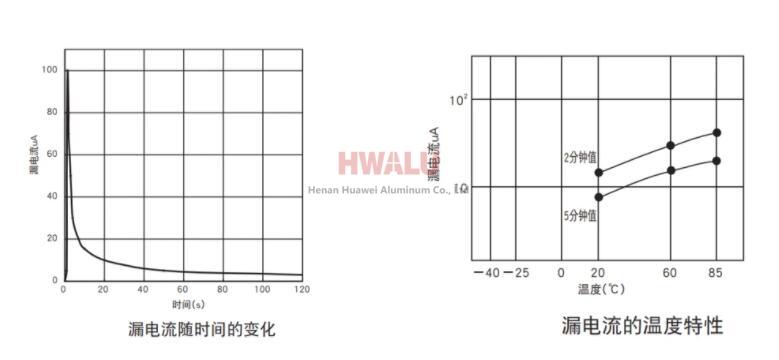

The leakage current will change with time, as shown in the figure, it will reach a stable value after decreasing with time. Therefore, the specification value of the leakage current is the value measured after applying the rated voltage for a period of time at 20°C.

When the temperature increases, the leakage current increases; when the temperature decreases, the leakage current decreases, and the applied voltage decreases, and the leakage current value also decreases.

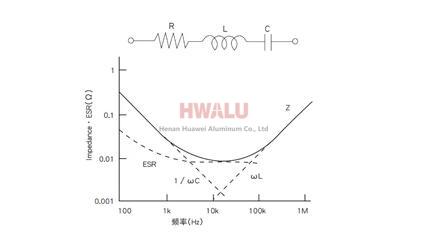

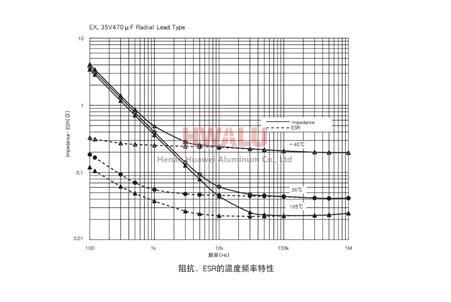

3.4. Impedance-frequency curve

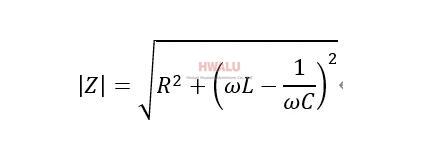

According to the model, the complex impedance of the capacitor is:

Modulus of impedance: 28

Draw the impedance-frequency curve as shown below:

1/ωC is capacitive reactance, and the straight line of capacitive reactance in the figure is angled at 45° downward. ωL is the inductive reactance, and its straight line forms an angle of 45° to the upper right corner. R represents equivalent series resistance. In the low frequency range, the influence of the frequency-dependent dielectric loss is large, so the R curve is downward. In the high frequency range, the resistance value of electrolyte and electrolytic paper dominates and is no longer affected by frequency, so the R value tends to be stable.

4. Ordinary aluminum electrolytic capacitor parameters

Manufacturers generally have various series of electrolytic capacitors, low ESR, long life, and high temperature. The ordinary products are performance, yes, the general temperature and life parameters are 85℃/105℃-1000h/2000h. This section is also about this kind of aluminum electrolytic capacitors.

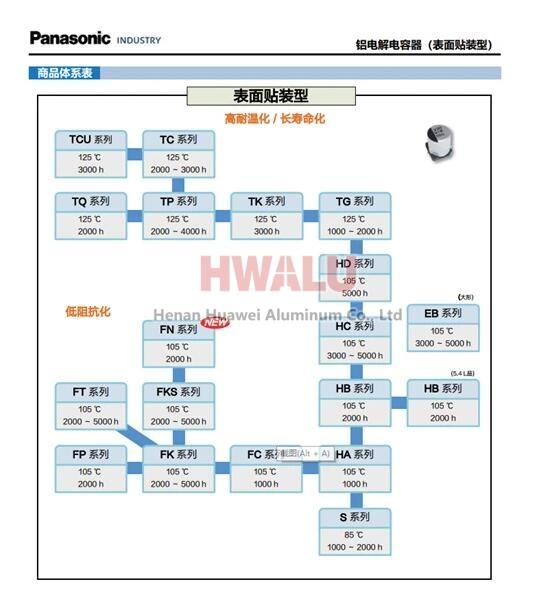

5. High-quality aluminum electrolytic capacitors

The high-quality aluminum electrolytic capacitors here are relative to ordinary aluminum electrolytic capacitors. In some special occasions, ordinary aluminum electrolytic capacitors cannot meet our requirements. In fact, aluminum electrolytic capacitor manufacturers usually provide multiple series of models. High-quality ones are mainly divided into three categories: high temperature resistance, long life, and low impedance.

The following picture shows the list of Panasonic's aluminum electrolytic capacitors.

The long life can reach 5000h, and the high temperature can reach 125℃.

6. Abnormal voltage

Application of abnormal voltage will cause heat and gas inside the capacitor to increase the internal pressure, and the increase in pressure will cause the valve to open or the capacitor to be damaged.

6.1, excessive voltage

Applying a voltage higher than the rated voltage will cause a chemical reaction of the anode foil (formation of a dielectric), resulting in a rapid increase in leakage current, which will generate heat and gas, and the internal pressure will also increase.

This chemical reaction will accelerate with the increase of voltage, current, and ambient temperature. As the internal pressure increases, the capacitor will open the valve or be damaged. It may also cause the capacitor capacity to decrease, the loss angle and the leakage current to increase, which may cause the capacitor to short-circuit.

6.2 Reverse voltage

Applying a reverse voltage will cause a chemical reaction of the capacitor's cathode foil. Like applying an excessive voltage, it will cause the leakage current to increase rapidly, and heat and gas will be generated inside the capacitor, which will cause the internal pressure to rise.

This chemical reaction will accelerate with the increase of voltage, current, and ambient temperature. At the same time, the electrostatic capacity decreases, the loss angle increases, and the leakage current increases.

Applying a reverse voltage of about 1V will cause a decrease in capacity; applying a reverse voltage of 2V-3V will cause a decrease in capacity, an increase in loss angle/or an increase in leakage current and shorten the life of the capacitor. If a larger reverse voltage is applied, the valve will open or the capacitor will be damaged.

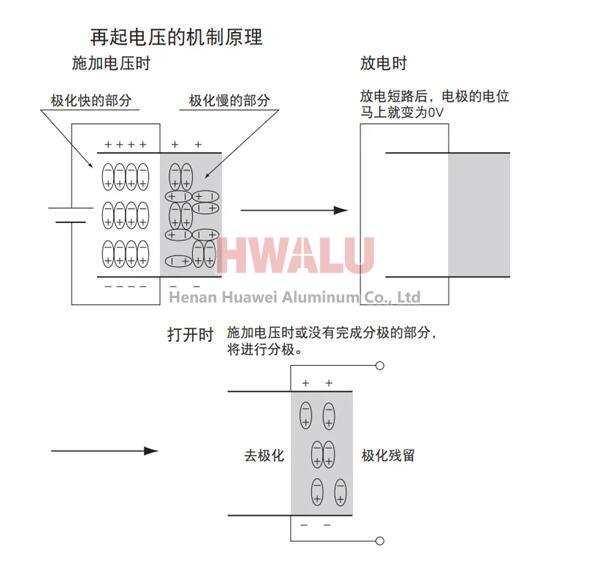

7. Restart voltage

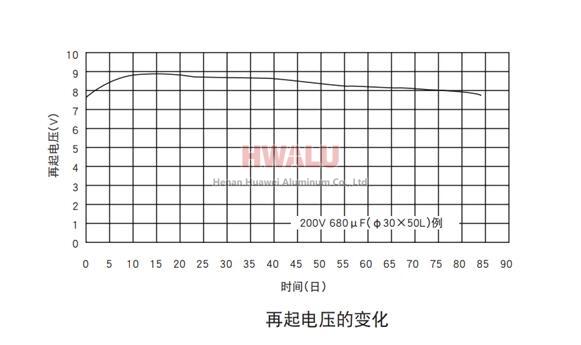

Charge the aluminum electrolytic capacitor, short-circuit its terminals, and then open the short-circuit line and leave it for a period of time, the voltage between the two terminals will rise again. The voltage at this time is called the restart voltage.

After a voltage is applied to the dielectric, an electrical change occurs inside the dielectric, and the surface of the dielectric carries the applied voltage and positive and negative reverse charges. (Polarization) Because the speed of polarization is fast or slow, after applying a voltage, set the voltage between the terminals to 0V, open the line, and place it. The slow polarization reaction potential generates a voltage between the terminals.

The time change of the restart voltage is shown in the figure. The peak value is reached after about 10-20 days after the two terminals are opened, and then gradually decreases. In addition, the resurgence power value of large products (screw terminal type, board self-supporting type) tends to increase.

After the re-voltage occurs, if the two terminals are accidentally short-circuited, the ignition will bring a sense of terror to the production line workers, and the low-voltage driving elements such as the circuit's CPU and memory may also be damaged. As a preventive measure, please discharge the accumulated charge with a resistance of about 100 to 1K ohms before use.

8. Life of aluminum electrolytic capacitors

8.1. The calculation principle of life

The life of aluminum electrolytic capacitors is generally affected by the phenomenon that the electrolyte evaporates outside through the seal, which is manifested as a decrease in the electrostatic capacity and an increase in the loss tangent value.

The relationship between the evaporation rate of the electrolyte and the temperature is expressed by Arrhenius' law:

k is: chemical reaction speed

A: Frequency factor

E: Activation energy

R: Gas constant

T: temperature

This formula illustrates the logarithmic relationship between the chemical reaction rate (the rate of electrolyte loss) and temperature. The temperature is determined by the ambient temperature of the aluminum electrolytic capacitor and the ripple current. Therefore, the ambient temperature and the ripple current determine the service life of the aluminum electrolytic capacitor.

The actual service life formula of aluminum electrolytic capacitors is as follows (different capacitors have some differences, just for reference):

Lx is the service life.

Lo is the guaranteed lifetime value (the lifetime declared in the specification).

To is the working temperature (the upper limit of the temperature in the specification).

Tx is the actual ambient temperature, the actual ambient temperature of the aluminum electrolytic capacitor.

It's easy to get that: every time the operating temperature of the capacitor increases by 10°C, the life of the capacitor is doubled