Anodized mirror aluminum sheet is an anodizing procedure. Anodes made of aluminium or metal alloy are placed in a liquid electrolyte to generate an aluminium oxide coating on the surface. Aluminum and its alloys can have an anodized layer with a thickness of hundreds of microns.

Additionally, the anodized gold aluminum mirror sheet's adsorption performance is excellent, allowing it to withstand corrosion, wear, & weathering. Then, electrolytic coloring can be applied. The following steps comprise the anodizing procedure: bronze or titanium electrochemical coloring, sealing, and unloading.

These plates can be found in many applications, from mobile phones to desktops to aircraft parts to precise instruments to radio equipment. The anodizing method is varied for each application.

In addition to its corrosion, stain, and fingerprint-resistant properties, an aluminum reflector sheet is also commonly utilized in electronic equipment because of its excellent thermal conductivity.

Aluminum alloy is increasingly being used as the hull structure of high-speed passenger ships due to the growth of the shipping industry worldwide and the associated demand for efficiency. Because seawater has severe corrosiveness, aluminum alloys frequently require surface treatment to increase their environmental adaptability.

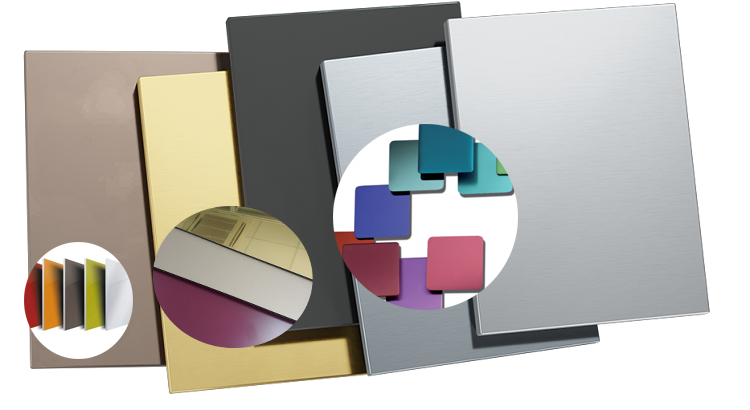

Huawei Aluminum is a major provider of anodized aluminum sheets in various alloys and thicknesses, such as 3 mm and 6 mm.