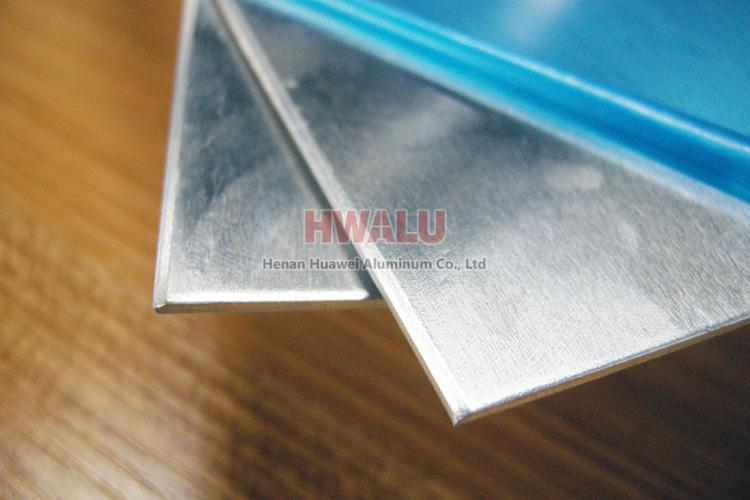

3003 aluminum sheet strength is not high (slightly higher than industrial pure aluminum), cannot be strengthened by heat treatment. Therefore, the cold processing method is used to improve its mechanical properties; 3003 aluminum plates have high plasticity in an annealing state, and the plasticity is better in half-cold machining. Hard mode is low, good corrosion resistance, good welding, and poor cutting.

3004 aluminum sheet strength is higher than 3003 aluminum plate, has excellent moldability and good corrosion resistance. It requires higher strength than 3003 aluminum plates.

3003 aluminum sheet is commonly used in ships, ships, vehicles, automotive welding, fire prevention requirements, strict pressure vessels, refrigeration devices, TV tower, drilling equipment, transport equipment, etc.

3004 Aluminum sheets are mainly used in chemical products production and storage devices, thin plate processing parts, building materials, building baffles, cable tubes, sewers, various lighting parts, beverage tanks, corrugated cardboards, building materials, colored aluminum plates, and electricity holders.