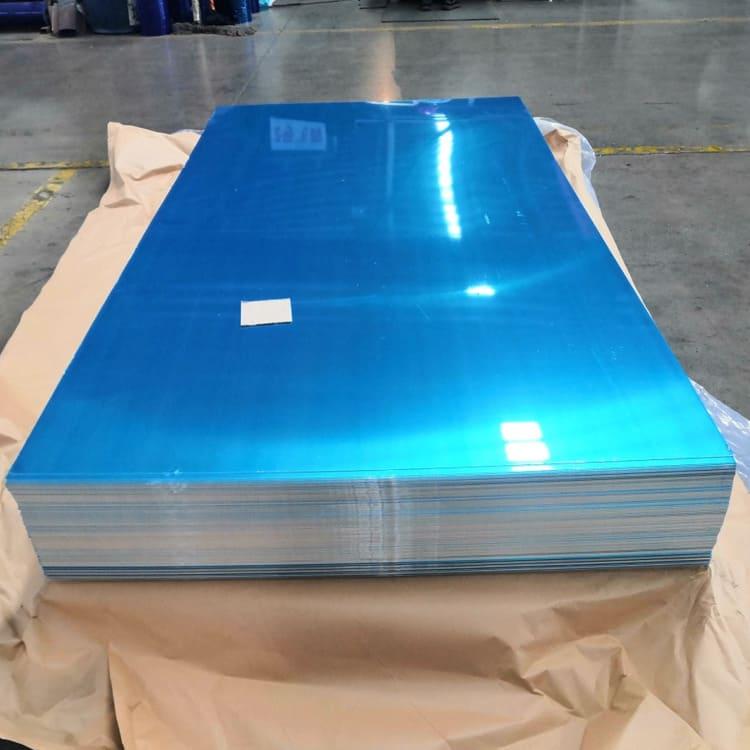

5052 Aluminum Sheet 5052 aluminum sheet is a non-heat-treatable alloy, but it can be strengthened by cold working to make it stronger; its biggest feature is its strong corrosion resistance. In addition, 5052 aluminum sheet can also be welded. Surface strengthening treatment, etc. 5052 aluminum production workshop Huawei Aluminum supplies a large ...

According to the product type, it can be divided into 5083 alloy metal aluminum sheet plate 5083 alloy metal aluminum coil The characteristics of 5083 metal aluminum alloy 5083 aluminum alloy has beautiful surface after anodized treatment. Good arc welding performance. The main alloying element in 5083 alloy is magnesium, which has good anti

Discovering the Process of Creating Jumbo Rolls of Aluminum Foil Parameters of aluminum foil raw material for lamination Alloy: 1235, 3003, 8011, 8079, 8021 etc Laminated plastic material: PET, PE, LDPE, LLDPE, OPP, PVC, etc Uses of aluminum foil for lamination Laminated Aluminium foil with plastic film Specifications Products: Alu foil/plastic la

Know more about aluminum strip 8011 What is a 8011 aluminum strip? 8011 aluminum strip is the product of aluminum coil and aluminum plate after slitting by slitting machine. It is mainly reflected in the width. Usually the width of aluminum strip does not exceed 800mm. The product is widely used in hardware and electrical appliances, lighting manufacturing

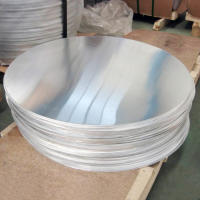

2014 alloy Aluminum disc circle with punching holes 2014 alloy Aluminum disc circle with punching holes 2014 aluminum circle applications Aluminum circle for human shelters air filter body and cover Human shelters air filter aluminum parts Human shelters air filter aluminum cover Human refuge air filter aluminum body 2014 aluminum ci

8011 alloy aluminum foil can be made into a foil container/foil platter, Our container foil jumbo coil is superior household material for packaging which features resistance to water and oil, isolation to light, and conductivity of heat. It is environmentally friendly and is reusable. 8011 alloy aluminum foil Parameters of 8011 alloy metal aluminium

Ⅰ: 6005 aluminum sheet description: Ⅰ-a: 6005 aluminum sheet Temper: 6005 aluminum sheet temper introduction O, T4, T6, T651.6005 Aluminum sheets are frequently found in aircraft construction. Henan Huawei Aluminum Co., Ltd 17 years experience professional China 6005 aluminum sheet Factory Manufacturers and Suppliers. The best price and best service are

1200 aluminum alloy sheet introduction 1200 aluminum plate is the industrial pure aluminum, with high plasticity, corrosion resistance, electrical and thermal conductivity, but low strength, heat treatment can not be strengthened, machinability is not good. 1200 aluminum sheet 1200 aluminum sheet plate chemical composition Alloy Si Fe Cu

what is a Wide Aluminum Sheet Plate? The international standard width of aluminum plates is 1000mm,1200mm,1220mm. We usually define aluminum sheets with a width of 1500mm or more as wide aluminum sheets. The general thickness of a wide aluminum plate can only be more than 1mm, the material is mainly 5052, 6061 aluminum alloy, commonly used thickness o

Reliable 1100 aluminum sheet/plate suppliers Huawei Aluminum - has been in the field of aluminum products production, processing and sales for more than 20 years, and is a professional manufacturer and wholesaler of aluminum products including 1100 aluminum sheet/plate, and can offer competitive prices for large orders. As a professional manufacturer, we

What Is Aluminum Foil? Because of its excellent characteristics, aluminum foil is widely used in food, beverage, cigarette,medicine, photographic substrate, household articles, etc., the aluminum foil is usually used as its packaging material. Aluminum foil is a soft metal with moisture-proof, airtight, shading, non-toxic, tasteless and high plasticity.Es

Our factory of Aluminium circle What is cold rolled aluminium disc circle Cold-rolled aluminum disc circles are made by cutting aluminum coils with a cold rolling mill.Common cold-rolled circle alloys include A1050 1060 1070 1100 3003 3004 5052, etc., which have good workability and corrosion resistance. Cold rolled aluminum disc circle Cold ro

1060 embossed aluminum type The product type, can be divided into 1060 embossed aluminum sheet plate 1060 embossed aluminum coil aluminum stucco embossed sheet coil Advantages of 1060 Embossed Aluminum 1. High-quality stucco embossed aluminum sheet 2. The chemical composition is reasonable and stable. 3. Accurate tolerances. 4. Goo

1.Type of coating structure 2/1: Apply twice on the upper surface, once on the lower surface, and bake twice. 2/1M: Coat the upper and lower surfaces twice and bake once. 2/2: Coat the upper and lower surfaces twice, and bake twice. 2.Uses of different coating structures: 2/1: The corrosion resistance and scratch resistance of the single-layer back pain

In markets, the quality of mirror sheet is quite different. It is important to know how to check the quality. Here we share with you three tips. First, the surface quality of the product 1. The surface of the mirror aluminum plate is not allowed to have cracks, corrosion, cracks, and the surface of the plate with a thickness greater than 0.6 mm is not allo

1. 4X8 aluminum plate hardness. Hardness is one of the references for the quality of aluminum plates, and it is necessary to pay attention. The hardness of the aluminum plate has a direct impact on the chemical composition of the selected alloy, and different states will also be different. From the common aluminum alloy raw materials, 7 series, 2 series, 4 s

5052 aluminum is one of the 5 series aluminum alloys and an important member of aluminum-magnesium alloys. Due to its outstanding performance, it has a very wide range of applications. Performance characteristics of 5052 aluminum 1. 5052 aluminum alloy plate, containing magnesium (2.5%) elements, has medium and high strength characteristics, and has good w

The representative models of 3 series aluminum plates are 3003, 3004, and 3A21, which can also be called anti-rust aluminum plates. 3 series aluminum sheets are widely used in pipeline insulation and automobile fuel tank industries. 3 series aluminium plate is a commonly used type of alloy aluminum plate. It is an aluminum alloy with manganese as the main al

It’s common to see a aluminum pan in kitchen,but there is still some people show their worries about using the aluminum pan.Before we give a conclusion,we need some reliable evidence.Let’s find out the result. Aluminium is a lightweight metal with very good thermal conductivity. It is resistant to many forms of corrosion. Aluminium is commonly available i

The element copper is added to 2014 aluminum alloy. As it is called hard molybdenum, it has high strength、good shavings and processing properties. 2014 aluminum sheet is usually used in some occasions with high strength and hardness (including heat). For example, heavy forgings, plate and extrusion materials are used for aircraft structures, the first st

The main chemical composition indicators of 5A06 aluminum plate are shown in the table below Chemical composition (mass fraction)/% Si Fe Cu Mn Mg Cr Ni Zn Ti Zr Others AL Single Total 0.40 0.40 0.10 0.50~0.80 5.8~6.8 - - 0.20 0.02-0.10 - 0.05 0.10 Remain The mechanical properties of 5A06 aluminum plate

5083 marine grade aluminum sheet, the content of Mg is about 4.0-4.9%, which higher than the Mg content in 5052 aluminum sheet. 5083 marine grade aluminum sheet has a moderate strength, offers excellent abilities in processing performance, weld ability and corrosion resistance, thus 5083 marine grade aluminum sheet is the material of choice for shipbuilding.

There is no shortage of competition between materials in the transportation market. The question is not which specific material to select; in general, the future lies with mixed material designs. The key question is which material is the optimal selection for a specific application, technically and economically; dependent on the type of vehicle, the envisage

The structures of the pharmaceutical packing foil and its advantages The pharmaceutical packaging foil is much required in the pharmaceutical field. Today we will discuss the structures and its advantages. The common pharmaceutical packaging material structure is: surface layer (protective layer), barrier layer (aluminum foil), inner layer (hea