ผลิตที่มีคุณภาพสูง 8011 อลูมิเนียมฟอยล์เกี่ยวข้องกับกระบวนการผลิตที่แม่นยำและมีการควบคุม. ตั้งแต่การเลือกวัตถุดิบไปจนถึงบรรจุภัณฑ์, แต่ละขั้นตอนมีส่วนช่วยในประสิทธิภาพและความน่าเชื่อถือของผลิตภัณฑ์ขั้นสุดท้าย. โดยปฏิบัติตามเหล่านี้ 8 ขั้นตอน, 8011 ผู้ผลิตอลูมิเนียมฟอยล์สามารถผลิตได้ 8011 aluminum foil that meets the stringent requirements of various industries, including food packaging, ยา, and household applications.

The production process of aluminum foil 8011

ขั้นตอน 1: Raw Material Selection and Preparation

To produce high-quality 8011 อลูมิเนียมฟอยล์, it is crucial to start with the right raw materials. Select aluminum ingots with a high purity level, โดยทั่วไป 99.7% or above, ensuring the desired properties in the final product. The ingots are then melted in a furnace to create a molten aluminum bath.

ขั้นตอน 2: หล่อต่อเนื่อง

The molten aluminum is poured into a continuous casting machine, where it is solidified into thin slabs. The continuous casting process helps achieve a uniform thickness and ensures the elimination of impurities.

ขั้นตอน 3: รีดร้อน

The solidified slabs are reheated and passed through a series of hot rolling mills. The rolling process reduces the thickness of the aluminum, resulting in a coil of semi-finished aluminum foil known as a "hot-rolled coil." The temperature, rolling speed, and reduction rate are carefully controlled to achieve the desired thickness and mechanical properties.

ขั้นตอน 4: รีดเย็น

The hot-rolled coil is then subjected to cold rolling, which further reduces the thickness and enhances the surface quality of the aluminum foil. The cold rolling process involves multiple passes through a series of rolling mills, gradually reducing the thickness to the required specifications. Intermediate annealing may be performed between passes to improve the material's formability and remove any residual stresses.

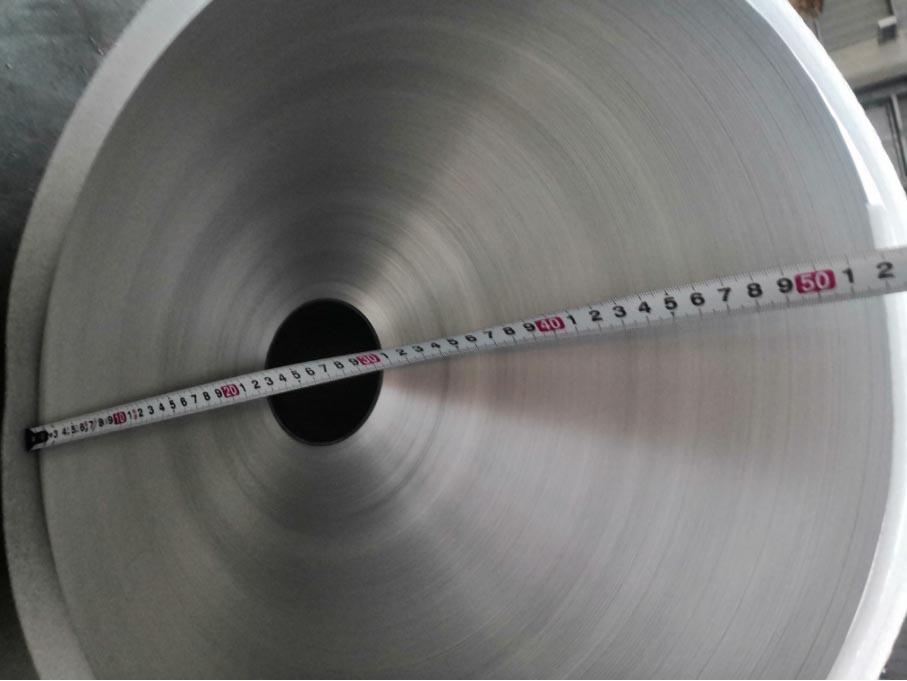

Cold Rolling Of 8011 อลูมิเนียมฟอยล์

ขั้นตอน 5: Annealing and Final Rolling

After cold rolling, the aluminum foil is annealed to restore its ductility and eliminate any work hardening. The foil is heated to a specific temperature and held for a certain duration, followed by controlled cooling. This annealing process ensures the foil remains flexible and easy to handle during subsequent processing. Once annealed, the foil undergoes final rolling to achieve the desired thickness, ความเรียบเนียน, and uniformity.

ขั้นตอน 6: Finishing Processes

After the final rolling, the aluminum foil is subjected to various finishing processes to meet specific requirements. These processes may include trimming the edges, slitting the foil into desired widths, and winding the foil into rolls of suitable lengths.

ขั้นตอน 7: Quality Control and Testing

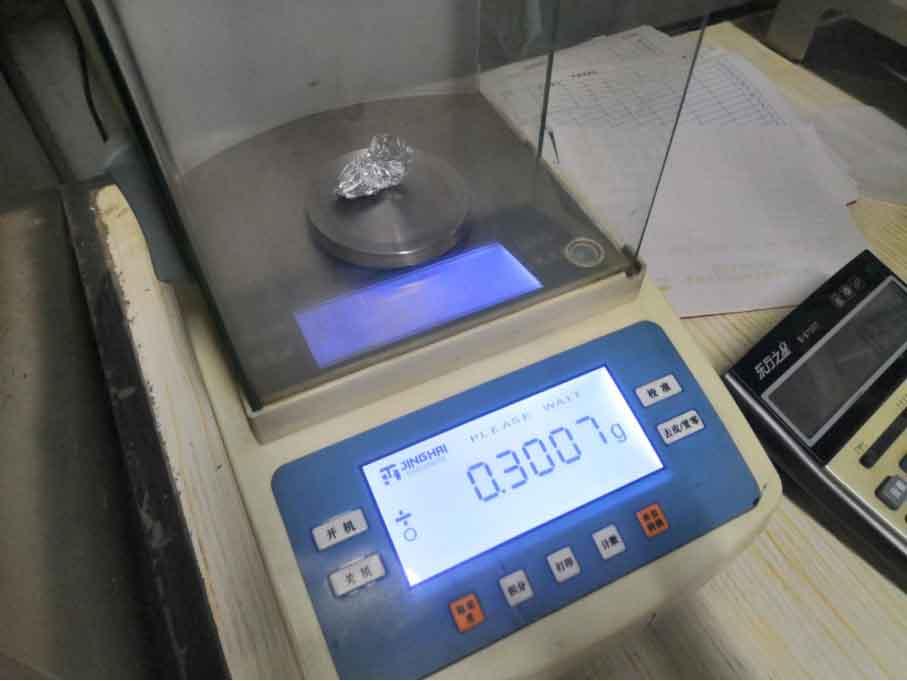

Throughout the production process, strict quality control measures are implemented to ensure the foil meets the required standards. Physical and mechanical tests, such as thickness measurement, tensile strength evaluation, and surface inspection, are conducted to verify the foil's quality and performance.

Quality Control and Testing Of 8011 อลูมิเนียมฟอยล์ |

Quality Control and Testing of aluminum 8011 ฟอยล์ |

ขั้นตอน 8: Packaging and Distribution

Once the 8011 อลูมิเนียมฟอยล์ passes the quality tests, it is carefully packaged to protect it from damage during transportation and storage. The foil rolls are usually packed in moisture-resistant packaging materials and labeled with relevant information such as specifications, batch number, and manufacturing date. The packaged foil rolls are then distributed to customers and end-users.

Packaging and Distribution of 8011 alloy aluminium foil