Sản xuất chất lượng cao 8011 lá nhôm bao gồm một quy trình sản xuất chính xác và được kiểm soát. Từ lựa chọn nguyên liệu đến đóng gói, mỗi bước đóng góp vào hiệu suất và độ tin cậy của sản phẩm cuối cùng. Bằng cách làm theo những 8 các bước, 8011 nhà sản xuất lá nhôm có thể sản xuất 8011 aluminum foil that meets the stringent requirements of various industries, including food packaging, dược phẩm, and household applications.

The production process of aluminum foil 8011

Bươc 1: Raw Material Selection and Preparation

To produce high-quality 8011 giấy nhôm, it is crucial to start with the right raw materials. Select aluminum ingots with a high purity level, tiêu biểu 99.7% or above, ensuring the desired properties in the final product. The ingots are then melted in a furnace to create a molten aluminum bath.

Bươc 2: Đúc liên tục

The molten aluminum is poured into a continuous casting machine, where it is solidified into thin slabs. The continuous casting process helps achieve a uniform thickness and ensures the elimination of impurities.

Bươc 3: Cán nóng

The solidified slabs are reheated and passed through a series of hot rolling mills. The rolling process reduces the thickness of the aluminum, resulting in a coil of semi-finished aluminum foil known as a "hot-rolled coil." The temperature, rolling speed, and reduction rate are carefully controlled to achieve the desired thickness and mechanical properties.

Bươc 4: Cán nguội

The hot-rolled coil is then subjected to cold rolling, which further reduces the thickness and enhances the surface quality of the aluminum foil. The cold rolling process involves multiple passes through a series of rolling mills, gradually reducing the thickness to the required specifications. Intermediate annealing may be performed between passes to improve the material's formability and remove any residual stresses.

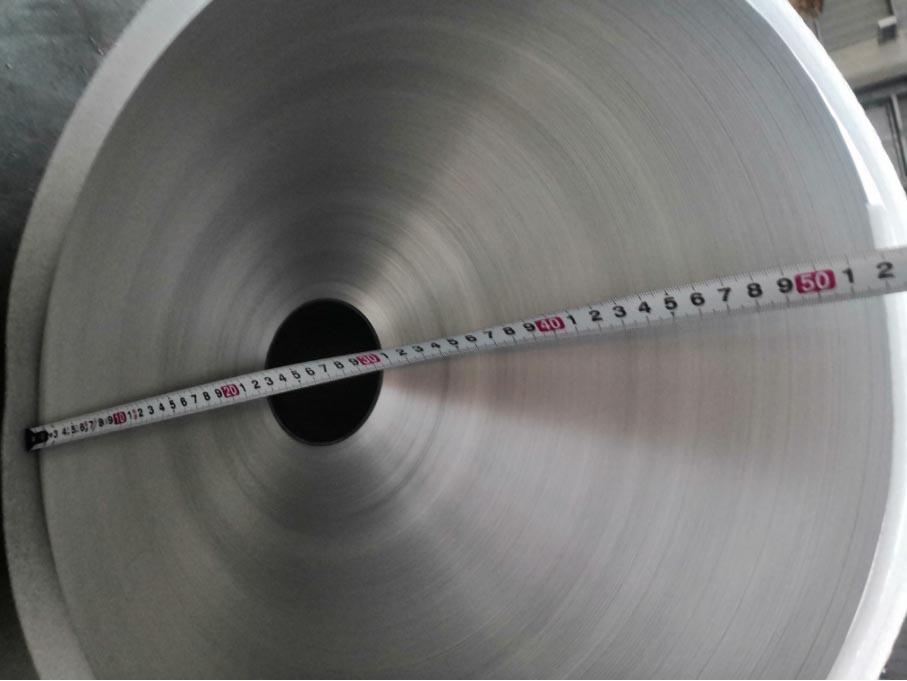

Cold Rolling Of 8011 giấy nhôm

Bươc 5: Annealing and Final Rolling

After cold rolling, the aluminum foil is annealed to restore its ductility and eliminate any work hardening. The foil is heated to a specific temperature and held for a certain duration, followed by controlled cooling. This annealing process ensures the foil remains flexible and easy to handle during subsequent processing. Once annealed, the foil undergoes final rolling to achieve the desired thickness, êm ái, and uniformity.

Bươc 6: Finishing Processes

After the final rolling, the aluminum foil is subjected to various finishing processes to meet specific requirements. These processes may include trimming the edges, slitting the foil into desired widths, and winding the foil into rolls of suitable lengths.

Bươc 7: Quality Control and Testing

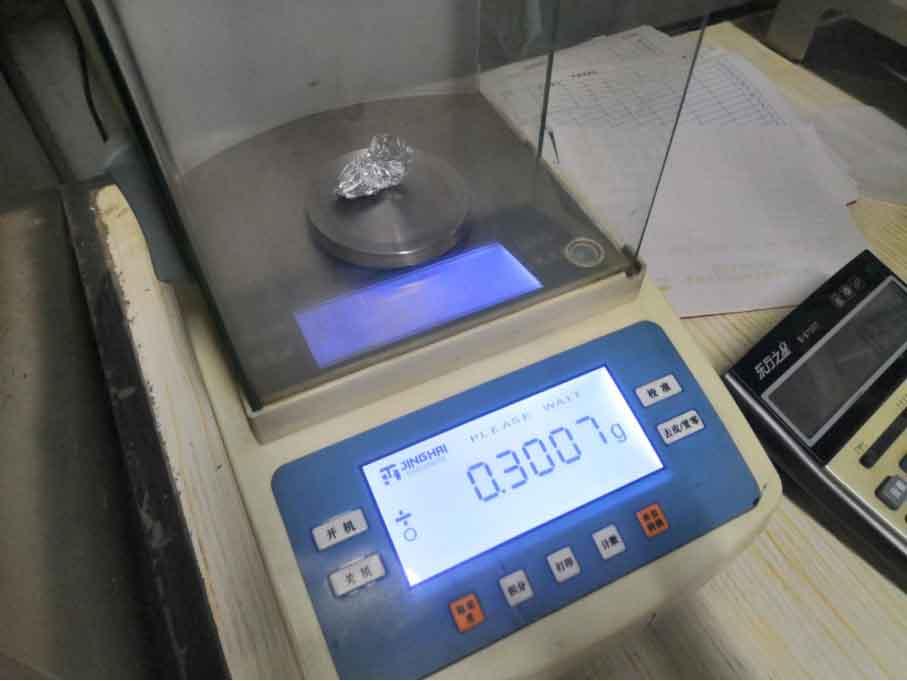

Throughout the production process, strict quality control measures are implemented to ensure the foil meets the required standards. Physical and mechanical tests, such as thickness measurement, tensile strength evaluation, and surface inspection, are conducted to verify the foil's quality and performance.

Quality Control and Testing Of 8011 giấy nhôm |

Quality Control and Testing of aluminum 8011 giấy bạc |

Bươc 8: Packaging and Distribution

Once the 8011 giấy nhôm passes the quality tests, it is carefully packaged to protect it from damage during transportation and storage. The foil rolls are usually packed in moisture-resistant packaging materials and labeled with relevant information such as specifications, batch number, and manufacturing date. The packaged foil rolls are then distributed to customers and end-users.

Packaging and Distribution of 8011 alloy aluminium foil