With the development and progress of society, people have more strict requirements for the performance of the product you need, which forces the manufacturer's selection requirements for producing raw materials. Traditional metal materials have gradually unable to meet the needs of manufacturing high performance products. Environmental protection is a hot topic today. Aluminum foil is used as an environmentally friendly, non-toxic, excellent material, and is widely used in conjunction with the trend of the times. As the new favorite of the times, the alloy 8011 aluminum foil is widely used in pharmaceutical packaging, food packaging, cable foil, dilute cover materials, sealing foil and other fields.

8021 aluminum foil and 8011 aluminum foil belong to 8 Series aluminum alloy, what is the difference between these two aluminum foil?

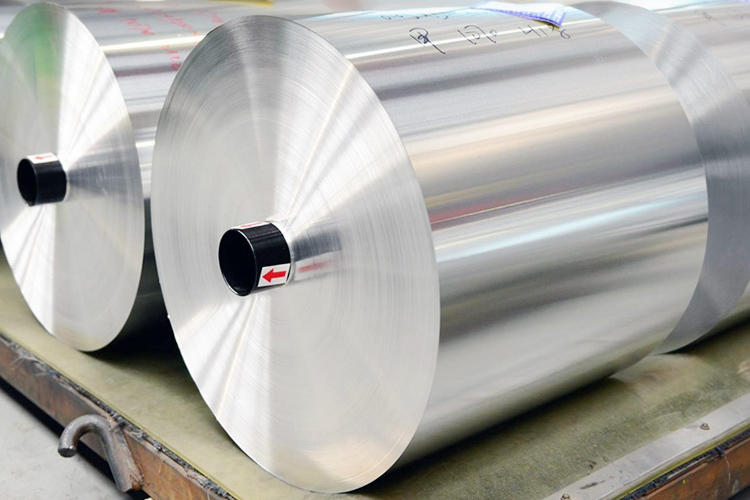

8011 aluminum foil introduction

The 8011 aluminum foil produced by our company is smooth, and the color is uniform, spotless, and good flat. At the same time, it also has excellent moisture-proof performance, shading and extremely high barrier capacity, strong mechanical properties, anti-burst, anti-puncture and tear resistance. Non-toxic, tasteless, hygienic. Composite, printing, and rubberized aluminum foil are widely used as packaging materials. 8011 aluminum foil with a thickness of 0.018-0.5mm can be processed, and can be customized according to customer requirements.

8021 aluminum foil introduction

8021 Aluminum foil has a thickness range of 0.018 mm to 0.2 mm, and the width can be controlled at 100-1650 mm according to customer requirements. 8021 Aluminum foil is the main product of food packaging and battery soft packaging aluminum foil. 8021 Aluminum foil has excellent moisture resistance, shading and high barrier ability. Non-toxic, tasteless, safe, and hygiene. Composite, printing, and rubberized aluminum foil are widely used as packaging materials.

Difference between 8011 aluminum foil and 8021 aluminum foil

- The strength and corrosion resistance of the 1,8011 aluminum foil are higher than 8021 aluminum foil;

- Aluminum foil 8011 has high strength, but its elongation and puncture resistance under the same state are lower than 8021 aluminum foil. Therefore, in drug packaging, the aluminum foil coating on the back of drug capsule plate is mostly 8021 aluminum foil, while the Blister aluminum and tropical aluminum with higher requirements for sealing and elongation are mostly 8021 aluminum foil and 8079 aluminum foil;

- Aluminum foil 8011 is more widely used and can be used in many fields such as drug packaging, food packaging, lunch box materials, tape foil, cable foil, milk capping materials, bottle capping materials, etc. while 8021 aluminum foil is relatively expensive and is mostly used in the packaging of lithium battery soft wrapped aluminum plastic film and blister drugs with relatively high requirements.