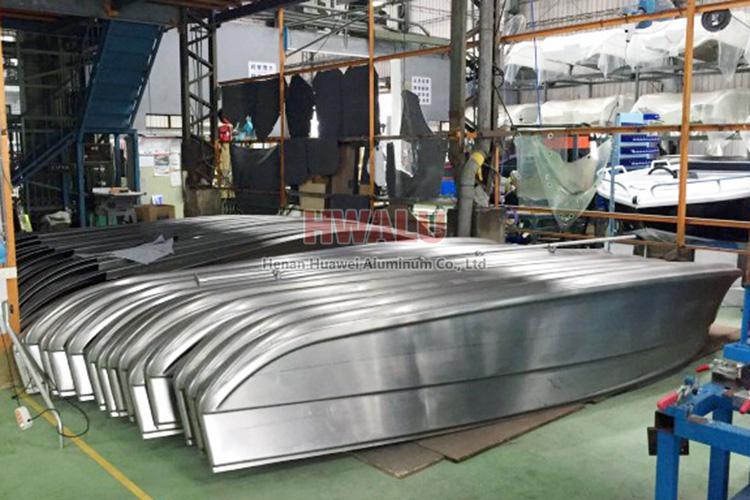

Marine grade aluminum sheet is specially treated to withstand use in water or wet environments. Usually, this is done by adding special alloys to the metal to make it corrosion-resistant. Most metals, such as aluminum, have marine grades.

Structural steel is the traditional material used in the shipbuilding industry due to its excellent mechanical properties and low manufacturing costs. However, the increasing demand for larger, yet light ships made designers search for alternative materials. Aluminum alloys were a great choice because they provided high corrosion resistance, weighed less, and were considered economical in the long run.

Hot sale alloy temper: 5052, 5083

Hot sale thickness: 4mm, 10mm

Types of Marine Grade Aluminum Alloys

Aluminum alloys are generally classified according to the primary alloying element added to aluminum and the alloys' ability to respond to thermal and mechanical treatment. Cast aluminum alloys are formed by pouring molten liquid metal into molds of requisite shapes and cooled; solid metal is mechanically deformed or forged or rolled to the required shape to form wrought aluminum alloys.

Marine grade wrought aluminum alloys usually comprise aluminum-magnesium (Al-Mg) alloys and aluminum-magnesium-silicon (Al-Mg-Si) alloys. They are generally used in structural shipbuilding, boat lifts, docks, and other offshore structural applications.

Cast aluminum alloys are used in numerous marine applications because casting processes can create relatively complex shapes, including ships' superstructures, structural components, interior fixtures and various supports. They are usually aluminum-silicon (Al-Si) or Al-Mg alloys.

The marine grade aluminum sheet stands for the aluminum sheet can be applied to the marine industry with good performance. The marine aluminum sheet alloy are 5000 series and 6000 series aluminum alloy, represented by 5083 aluminum plate, including 5083 aluminum plate, 5086 aluminum plate, 5052 aluminum plate, 5383 aluminum plate, 5454 aluminum plate, 5456 aluminum plate, 5754 aluminum plate, 6061 aluminum plate, 6063 aluminum plate, etc. The features of marine aluminum plate are low density, high strength, ship weight reduction, high corrosion resistance, durability, economical and environmental protection.

To the specific application of marine grade aluminum sheet:

On the ship’s side, the outer bottom plate of the ship can be made of 5083 aluminum plate, 5086 aluminum plate, 5456 aluminum plate and 5052 aluminum plate. The excellent corrosion resistance of the marine aluminum sheet can better resist the erosion of sea water and prolong the life of the ship.

The top and side plates of the marine ship container can be made of 3003 aluminum plate, 3004 aluminum plate and 5052 aluminum plate. The 3003 aluminum plate has good anti-rust effect. Under the long-term sea wind and rain, the rust of the top plate is reduced to some extent.

The wheelhouse can be made of 5083 aluminum plate, 6N01 aluminum plate and 5052 aluminum plate. The non-magnetic plate of the aluminum plate makes the compass unaffected and ensures the correct direction of the ship during navigation.