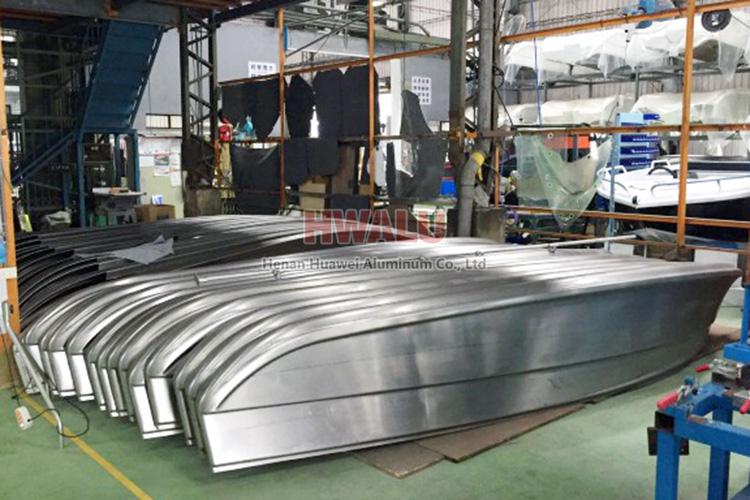

What material can make a boat?

Marine materials generally use carbon steel, alloy steel, non-ferrous metal aluminum alloys, and marine profiles. The quality of steel is strong, but the weight and corrosion resistance are far inferior to aluminum alloy plates, so the materials used for ship plates are generally aluminum alloy plates.

Due to the harsh marine environment in which ships work, marine grade aluminum sheet plates must be able to withstand the corrosion of seawater, electrochemistry, marine organisms, and microorganisms. Because of this, scientific research reports suggest that aluminum plates can form dense aluminum oxide films, effectively blocking oxygen and humidity. This is also an important reason for the corrosion of the hull. Therefore, aluminum sheets are widely used for ship hulls.

marine grade aluminium 5083

The Most Popular Marine Grade Aluminum Alloy Plate

Aluminum alloy has the characteristics of light weight and seawater corrosion resistance, and the hull made can also withstand large wind and wave shocks and immersion in wet environments;

Among the 1-8 series aluminum alloys, 5000 series and 6000 series aluminum sheets are the most common marine aluminum sheets.

5000 series marine grade aluminum alloy:5052 5083 5086 5754

6000 series marine grade aluminum alloy:6061,6065,6083

Marine grade aluminum sheet 5052 is the most common type of 5 series and 6 series, because marine grade 5052 has good metal properties, the material is strong and durable, it can also be used for a long time in wet and underwater environments, and it is not easy to be corroded and oxidized .

Parameters of marine grade aluminum plate

| Marine Grade Aluminum Parameters Construction | |

|---|---|

| Alloy |

|

| Temper | Soft HO, H12, H13, H14, H15, H16, H18, H19, H20, H111, H112, H114, H116, etc |

| Sizes: | 4x8 aluminum sheet, 4x10 aluminum sheet, 5x10 aluminum sheet, |

| Thickness (customized) | 2mm, 2.5mm, 3mm , 3.5mm, 4mm, 5mm, 6mm, 10mm ( thick ), etc |

| Width | 100mm-2800mm |

| Surface treatment | Anodized , color coated , mirror marine aluminum sheet, etc |

Marine grade aluminum alloy sheet series

5052 marine grade aluminum sheet for boat

Marine grade aluminum 5052 aluminum alloy belongs to the al-mg series of alloys. Due to its excellent weldability and corrosion resistance, it is very suitable for marine environments and is an ideal material for shipbuilding. Widely used in the manufacture of ship plate metal parts, bottom plates, portholes, bottom plates, side plates, etc.

marine grade aluminum 5052

5083 metal marine grade aluminum alloy plate for boat

Marine grade aluminum 5083 alloy aluminium has higher strength than marine grade 5052 alloy aluminum and has exceptional thermal conductivity. In tempered condition, it retains good formability due to excellent ductility. It is highly suitable for welding and can be hardened by cold work. Because Alloy 5083 exhibits excellent resistance to general corrosion, it is used in marine applications. Since Alloy 5083 is capable of withstanding extremely low temperatures without brittleness or loss of properties, it is especially suited to the cryogenic market.

Alloy 5083 also retains exceptional strength after welding. It has the highest strength of the non-heat-treatable alloys but is not recommended for use in temperatures in excess of 65°C.

6061 marine grade aluminum

5086 marine grade aluminum sheet for boat

5086 alloy aluminum belongs to rust-proof aluminum and is widely used in occasions requiring high corrosion resistance, good weldability and medium strength: such as weldable parts of ships, automobiles, and aircraft plates; pressure vessels and refrigeration devices that require strict fire protection, TV tower, exploration equipment, transportation equipment, missile parts, armor, etc.

marine aluminum plate for billboards

5754 metal marine aluminum alloy for boat

5754 alloy aluminum belongs to Al-Mg-Si aluminum alloy, it has a wide range of applications in the field of the high-level aluminum processing industry. With the vigorous development of the railway transport market, and the globalization of the automobile era, the processing needs of marine-grade aluminum alloy, rail transportation, high-grade car complex parts are increasing, 5754 alloy aluminum has a great market prospect. 5754 alloy aluminum of different heat treatment temper is the main material of the automobile manufacturing industry (car door, mold, seals) and canning industry.

marine grade aluminum sheet plate

Packaging of marine grade aluminum sheets

Standard export seaworthy wooden pallet with

- Plastic film protection.

- Hard Kraft Paper.

- Steel Bar Bunch.

- Wooden plate.

5083 aluminum sheet price

Why choose marine grade aluminum 5052 sheet?

There are many models of 5 series aluminum alloy sheets that are suitable for marine aluminum sheets, so why choose 5052 aluminum sheets as the first choice for marine aluminum sheets?There are four reasons as follow.

1. Marine grade aluminum 5052 has high strength and specific modulus. Since the elastic modulus and density of aluminum alloys are roughly the same, which are closely related to the structural strength and size of the ship, increasing the yield strength within a certain range can reduce the tension of the ship structure. 5052 aluminum plate is of medium strength and can have excellent corrosion resistance and weldability at the same time.

2. Marine grade aluminum 5052 has excellent weldability. 5052 aluminum plate is not prone to cracks during welding.

3. Marine grade aluminum 5052 has excellent corrosion resistance. 5052 aluminum plate is a typical rust-proof aluminum plate, which has good corrosion resistance, can adapt to harsh marine environment and is durable.

4. The density of 5052 marine grade aluminum sheet is small. Aluminum alloy has a small specific gravity, which can reduce the weight of the ship board.

Huawei Aluminum Quotation

| Date | LME | LME Weekly Price | 2023-04 LME Average | 2023-04 SMM Average |

| 2023-05-03 | 2330$ | 2333.3$ | 2341.00$ | 2712.08$ |

| 2023-05-02 | 2353$ | |||

| 2023-04-28 | 2342$ | |||

| 2023-04-27 | 2302$ | |||

| 2023-04-26 | 2339.5$ | |||

| Notes

1. Prices are updated at 10:00 am on weekdays. |

||||