6061 aluminum discs introduction

What is a 6061 aluminum circle?6061 aluminum discs is an aluminum-silicon-magnesium alloy, strengthened by precipitation hardening. This alloy has medium strength, formability, weldability, machinability, and corrosion resistance.6061 aluminum discs are made of one of the most versatile of all the aluminum alloy discs. 6061 aluminum discs are the alloy of choice for all-purpose applications.

6061 T651 aluminum circle chart

Huawei 6061 aluminum discs have a T651 temper, indicating it has been solution heat treated followed by minimal stretching to reduce stresses in the material. The material was then artificially aged to allow the alloying elements to precipitate out of the material, to give immediate maximum strength.

6061 aluminum discs Features

The advantages of 6061 aluminum disc have the following four points:

1. Heat treatment to strengthen, high-impact toughness.

2. Excellent thermoplastic, welding performance, and corrosion resistance.

3. No deformation after processing, the surface is very smooth and easy to anodize and color.

4. Excellent interface characteristics, high strength, good usability, strong corrosion resistance.

Parameters of 6061 aluminum circles

| Alloy Number | 6061 |

|---|---|

| Equivalent alloy name | a6061 aluminum , 6061a, aa6061, 6061aa, al6061 |

| Temper | O, H112, T2, T3, T4, T5,T6, T651,T650, T651, T851 etc |

| Diameter | 50mm to 1000mm |

| Thickness | 0.5mm, 0.6mm, 0.7mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm etc |

| Characteristics | Heat treatable alloy with excellent strength. |

Applications of round 6061 aluminum discs

| Application | Scenes | Application show |

|---|---|---|

| Mechanical parts | aluminum circle for car wheels |  |

| Kitchenware | aluminum circle for aluminum pan |  |

| Furniture | aluminum circle for lampshade |  |

| Traffic sign | aluminum circle for road sign |  |

| Precision Machining | aluminum circle for aluminum cans |  |

| Other applications: electronic instruments, shipbuilding, Automobile, car wheels, deep tubes, etc. | ||

Huawei aluminum circle information:

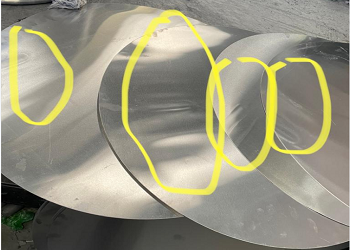

A customer complaint about aluminum circle products in 2021

COMPENSATION PROPOSAL

PI NUMBER: HWA210702 DATE: 2021.7.8

SELLER: HENAN HUAWEI ALUMINUM CO., LTD

BUYER: U******., S.A. END USER: A**** S.A.

1. CLAIM CONTENT

There were about 143pcs of Aluminium Circle with problems of wrinkles and indentations on the surface. The customer (ALTURA) tried to use them but the finished products had cracks and unevenness, which were unacceptable. Therefore, the customer had to dispose of this part of the material and file a customer complaint.

2. RELATED PHOTOS

| RELATED ALUMINUM CIRCLE PHOTOS | |

|---|---|

|

|

|

|

|

|

|

|

|

|

3. COMPENSATION PROPOSAL

Considering the customer’s cost of purchasing which includes CIF price, Destination port charge, domestic transportation costs, etc., and the current LME Aluminium price, if the customer treats this problematic material as scrap, we company will pay an additional $3**0 as compensation supplement.

4. SPECIFIC IMPLEMENTATION

The compensation part will be deducted at one time from the final payment of the order HWA220304 signed on March 9, 2022.

The above is the preliminary compensation proposal from Henan Huawei Aluminum Co., Ltd about the claim of order HWA210702. If you have any questions or objections, please feel free to communicate with us.

Best regards,

HENAN HUAWEI ALUMINUM CO., LTD

DATE: March 30, 2022

Huawei Aluminum Quotation

| Date | LME | LME Weekly Price | 2023-04 LME Average | 2023-04 SMM Average |

| 2023-05-03 | 2330$ | 2333.3$ | 2341.00$ | 2712.08$ |

| 2023-05-02 | 2353$ | |||

| 2023-04-28 | 2342$ | |||

| 2023-04-27 | 2302$ | |||

| 2023-04-26 | 2339.5$ | |||

| Notes

1. Prices are updated at 10:00 am on weekdays. |

||||