As an important lightweight material, aluminum honeycomb panels are widely used in the aviation manufacturing industry, and have been used in foreign railway vehicles for a long time, and their use is quite extensive. The domestic use of aluminum honeycomb panels only in recent years, although it has achieved certain results, the scope of its application is still very limited, the understanding of the characteristics of honeycomb sandwich material and the scope of application still needs to be further strengthened and expanded.

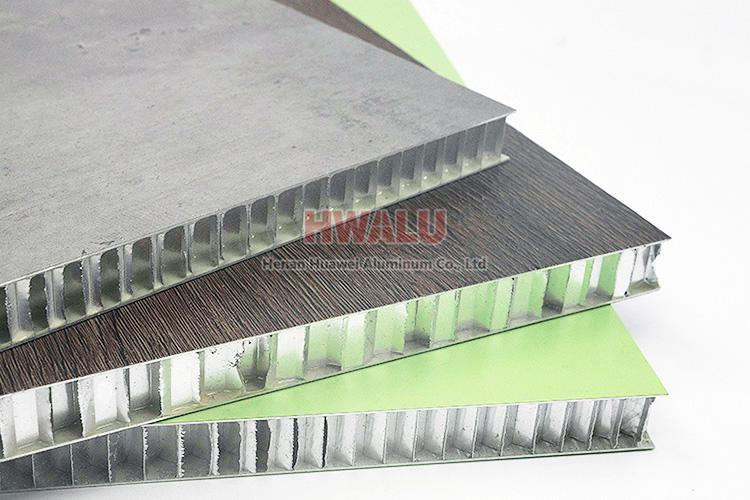

Aluminum honeycomb sheet upper and lower base plate, panel, mainly use high-quality 3003-H24 aluminum or 5052-H14 alloy aluminum plate, aluminum thickness between 0.4mm-3.0mm. The aluminum honeycomb core is made of 3003 aluminum foil/3004 aluminum foil with the thickness of 0.02~0.06mm, and the edge length of aluminum honeycomb is 5mm, 6mm, 8mm, 10mm, 12mm, etc.

Aluminum honeycomb panel is a composite material made of aluminum honeycomb core and surface material bonding, in summary, aluminum honeycomb panel has the following basic characteristics.

(1) Light weight, high specific strength, especially high bending stiffness, the same quality of aluminum honeycomb panel is about 5 times the bending stiffness of aluminum alloy.

(2)High surface flatness and high temperature stability, easy to shape and not easy to deformation, aluminum honeycomb panels can not only be made into flat panels, and can be manufactured into double bending, single bending panels, made into vehicle parts after disassembly and assembly is convenient.

(3) excellent corrosion resistance, insulation and environmental adaptability, can adapt to the railroad rolling stock and passenger cars a variety of harsh operating environment; In addition, according to the need, this type of plate can be used surface painting or surface paste fire board treatment, to achieve good decorative, fire resistance.

(4) Unique resilience to absorb vibration energy, with good sound insulation and noise reduction effect.

(5)High fireproof grade to meet the requirements.

(6)Smoke density after encountering fire meets high grade international railroad fire protection standards, with good self-extinguishing properties; low exothermic value, able to form a refractory layer, can reduce the smoke and toxic gases released, with excellent environmental performance.

(7) Excellent molding manufacturing process, can meet the requirements of complex shape and high stability requirements of railway vehicle interior parts.