aluminum alloy 5052 plate shape concept

- Plate shape usually refers to the straightness of the plate and strip material, that is, whether the plate and strip material parts produce waves, warpage, side bending and scooping, etc..

- Plate shape is an important quality indicator of the plate and strip. The shape of the plate depends on whether the extension of the strip along the longitudinal direction is equal when rolling, the uniformity of the thickness of the cross-section of the billet before rolling, the roll type and the actual roll shape formed by the bending deformation of the roll when rolling. It can be seen that the plate shape and transverse thickness accuracy of the two are closely related

aluminum alloy 5052 plate shape in the definition of the wave

Waves are caused by the inconsistent extension of the plate strip width to each part of the longitudinal when rolling. When the plate strip material on both sides of the extension is greater than the middle, it produces symmetrical bilateral waves; conversely, if the middle extension is greater than the two sides, it produces intermediate waves; if the amount on both sides is not equal, the amount of pressure down the side of the extension is large, it produces a single-sided wave or side bend (sickle bend). When the rolled part leaves the roll exit up or down, or along the width of the arc bend called warpage.

aluminum alloy 5052 plate shape of the representation method

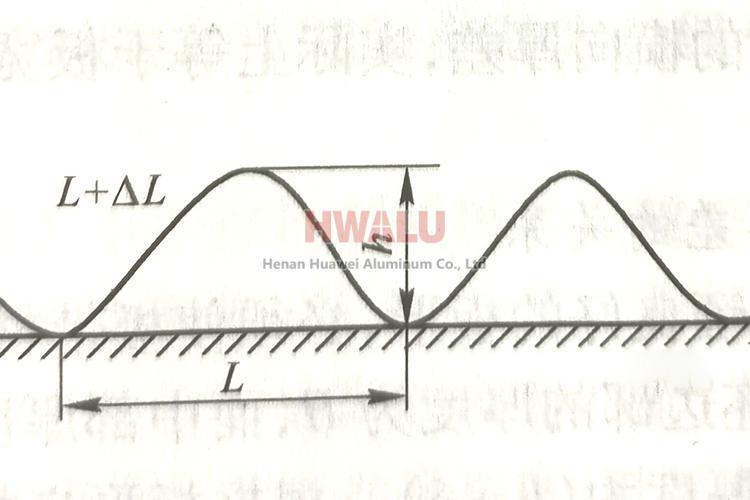

Quantitative representation of the plate shape, both in the production of the need to measure the quality of the plate shape, but also to study the plate shape control and the need to achieve the plate shape control. At present, according to the different purposes of use of different countries, there are different methods of representation. One of the 5052 aluminum sheet plate shape representation method is to cut a section of the strip on the platform, such as the shortest longitudinal strip as a straight line, the longest longitudinal strip as a sine wave, then the definition of the plate strip unevenness (λ) as follows

λb= (h/L)×100%

The formula h - wave height; λb - wavelength.

When the λb value is greater than 1%, the wave or warpage will be more obvious, the general production requirements after leveling the plate λb value should be less than 1%