Zdolność do obróbki cieplnej stopu aluminium zależy od jego składników stopowych i ich zdolności do tworzenia wydzieleń lub faz nadających się do obróbki cieplnej. Podstawowa różnica pomiędzy 5000 seria i 6000 Seria stopów aluminium leży w ich pierwiastkach stopowych, co skutkuje odrębnymi właściwościami obróbki cieplnej.

5000 Seria Stopy aluminium:

The 5000 serie stopów aluminium, Jak na przykład 5052 I 5083, are primarily composed of aluminum, with magnesium (Mg) as the main alloying element. These alloys are not considered heat treatable because they do not contain elements that readily form heat-treatable precipitates, jak miedź (Cu) or zinc (zn). While magnesium can contribute to increased strength through cold working (strain hardening), it does not form strengthening phases when heated to specific temperatures and then quenched.

Instead, 5000 series alloys are often used in their annealed or H32/H34 temper conditions, where they have good formability and moderate strength. They can be strengthened through cold working, but this does not involve heat treatment.

6000 Seria Stopy aluminium:

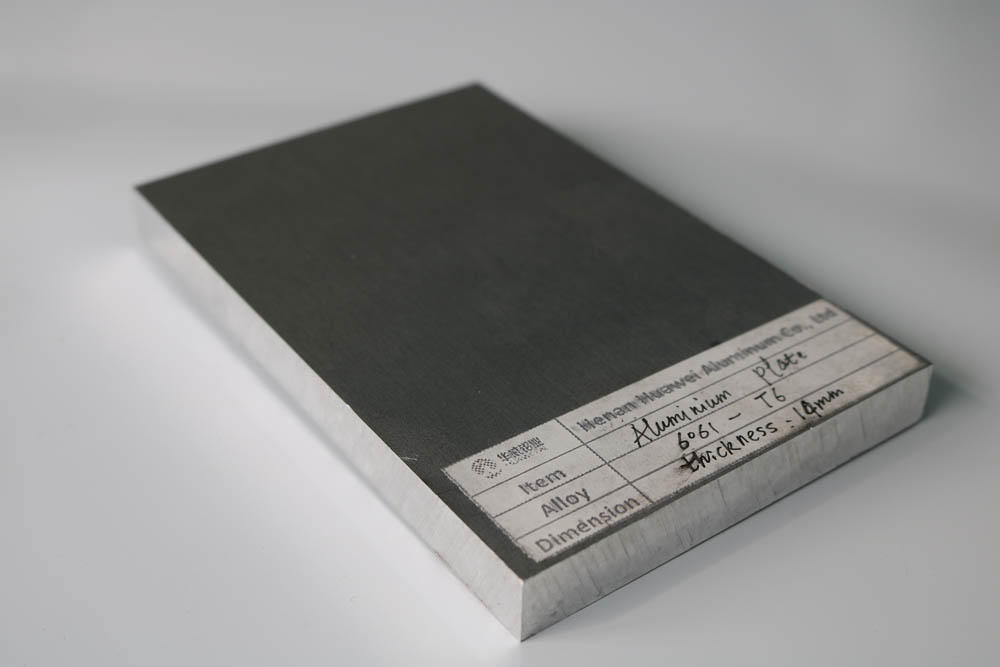

The 6000 serie stopów aluminium, including popular alloys like 6061 I 6063, contain both magnesium (Mg) i krzem (I) as their primary alloying elements. These alloys are known as heat-treatable because they can be significantly strengthened through a heat treatment process called precipitation hardening (also known as T6 temper or artificial aging).

In the precipitation hardening process, the alloy is heated to a specific temperature, typically around 350°F to 450°F (175°C to 230°C), and then quenched to rapidly cool it. This forms fine precipitates of a strengthening phase (usually Mg2Si) within the aluminum matrix. These precipitates hinder dislocation movement, making the alloy stronger and more durable.

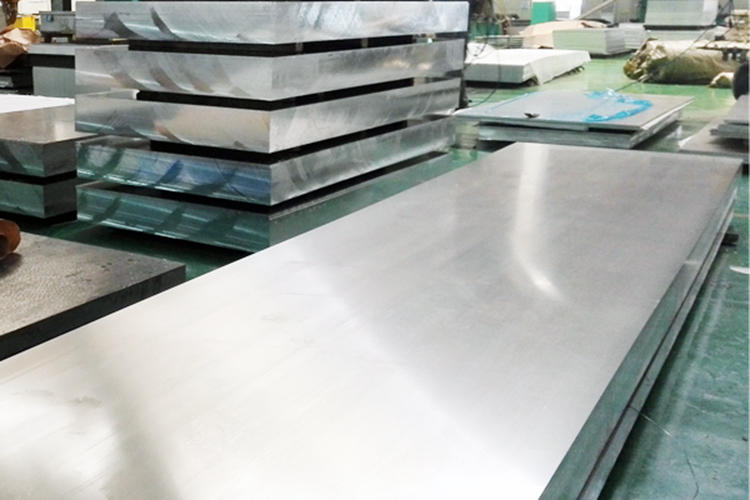

Aluminiowa płyta 6061

W podsumowaniu, the difference in heat-treatability between 5000 seria i 6000 series aluminum alloys is primarily due to their alloying elements. While magnesium is the primary alloying element in both series, 6000 series alloys also contain silicon, which enables the formation of heat-treatable precipitates and allows for substantial strengthening through heat treatment. Odwrotnie, 5000 series alloys lack the necessary elements for this precipitation hardening process and are thus not considered heat treatable.