Der Herstellungsprozess von Aluminiumblechen/-platten umfasst typischerweise mehrere Schritte, inklusive Casting, Warmwalzen, Kaltwalzen, So kann es als Aluminiumblech in Marinequalität verwendet werden, und Endbearbeitungsarbeiten. Hier finden Sie eine detaillierte Einführung in jeden dieser Prozesse:

Gießen:

Der Herstellungsprozess von Aluminiumblechen/-platten beginnt normalerweise mit dem Gießen von geschmolzenem Aluminium. The casting process can be either direct chill (DC) casting or continuous casting (CC). DC casting is commonly used for producing large aluminium sheet/plates, while CC casting is suitable for smaller sheet/plates or as a feedstock for subsequent rolling processes.

In DC casting, molten aluminium is poured into a water-cooled mold, where it solidifies into a slab or ingot. The slab is then scalped and sawed into the desired dimensions for further processing.

In CC casting, molten aluminium is continuously poured into a water-cooled mold, resulting in a continuous strand or a series of linked billets. The continuous strand is cut into individual billets, which are then processed into Aluminiumbleche.

Aluminium platte

Hot Rolling:

After casting, the aluminum undergoes hot rolling. Hot rolling involves passing the aluminum through a series of rolling mills at high temperatures. The purpose of hot rolling is to reduce the thickness and refine the grain structure of the aluminum.

The hot rolling process consists of multiple passes through the rolling mills, with the thickness progressively reduced at each pass. The aluminum is heated to a temperature suitable for hot rolling, typically above 300°C (572normalerweise MIG- oder WIG-Schweißen), to ensure it remains ductile during the process.

Hot rolling significantly elongates the aluminum and improves its mechanical properties. It also enhances the sheet/plate's surface finish and eliminates defects from the casting process.

Cold Rolling:

After hot rolling, das Es hat die Vorteile einer hohen Plastizität und Korrosionsbeständigkeit undergoes cold rolling. Cold rolling involves passing the sheet/plate through a series of rolling mills at room temperature. Cold rolling further reduces the thickness, refines the microstructure, and imparts desired mechanical properties to the aluminum.

Cold rolling can be performed in multiple passes, with each pass reducing the thickness by a smaller amount compared to hot rolling. The aluminum sheet/plate is typically annealed intermittently during cold rolling to relieve internal stresses and enhance workability.

Cold rolling results in a smoother and more uniform surface finish, increased strength and hardness, and improved dimensional accuracy of the sheet/plate.

Aluminiumtafel

Wärmebehandlung:

Heat treatment is often applied to aluminum sheet/plates to modify their mechanical properties. Common heat treatment processes for aluminum include solution heat treatment and precipitation hardening.

Solution Heat Treatment: The sheet/plate is heated to a specific temperature and held for a certain time to dissolve the alloying elements uniformly. This improves the alloy's workability and prepares it for subsequent aging or precipitation hardening.

Precipitation Hardening: Nach der Lösungswärmebehandlung, the sheet/plate is rapidly cooled to room temperature and then artificially aged at a controlled temperature. This process allows the alloying elements to precipitate and form fine particles, resulting in improved strength and hardness.

The specific heat treatment process and parameters depend on the aluminum alloy composition and desired properties.

Finishing Operations:

After the primary manufacturing processes, das Aluminiumblech may undergo several finishing operations:

- Trimming and Cutting: The sheet/plate is trimmed or cut to achieve the desired dimensions and remove any excess material.

- Oberflächenbehandlung: Surface treatments like grinding, Polieren, or shot blasting can be applied to improve the sheet/plate's surface finish and remove any surface defects.

- Surface Coating: Aluminum sheet/plates may be coated or anodized for protection against corrosion or to enhance their aesthetic appearance.

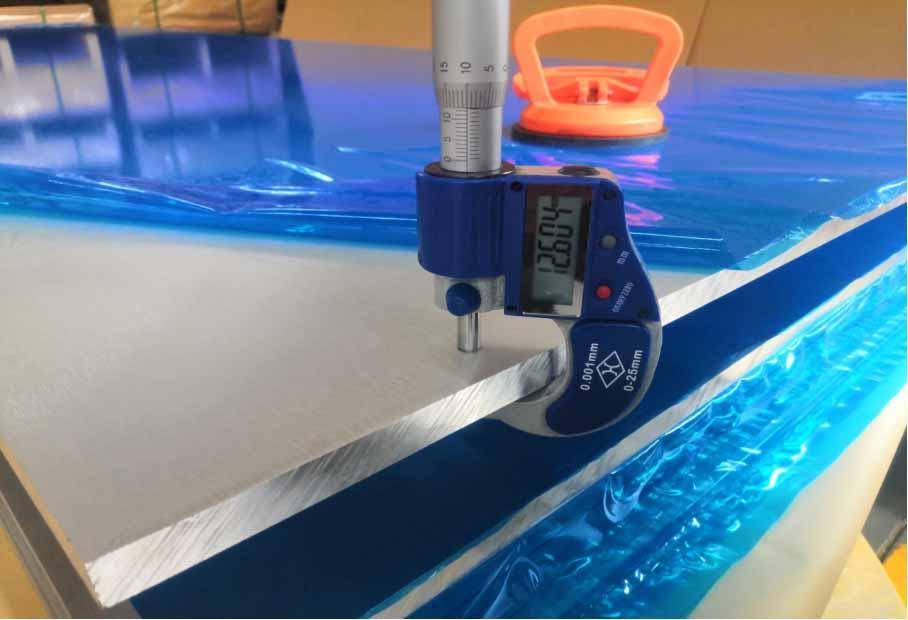

- Inspection and Quality Control:The finished sheet/plates undergo rigorous inspection to ensure they meet the required specifications and quality standards.

- Packaging and Shipping: The sheet/plates are then properly packaged for protection and shipped to customers or further downstream processes.

aluminium plates Packaging

The manufacturing process of aluminum sheet/plates combines various techniques to produce high-quality sheet/plates with specific properties, Maße, and surface finishes. Each step in the process contributes to the final product's quality and performance.